Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

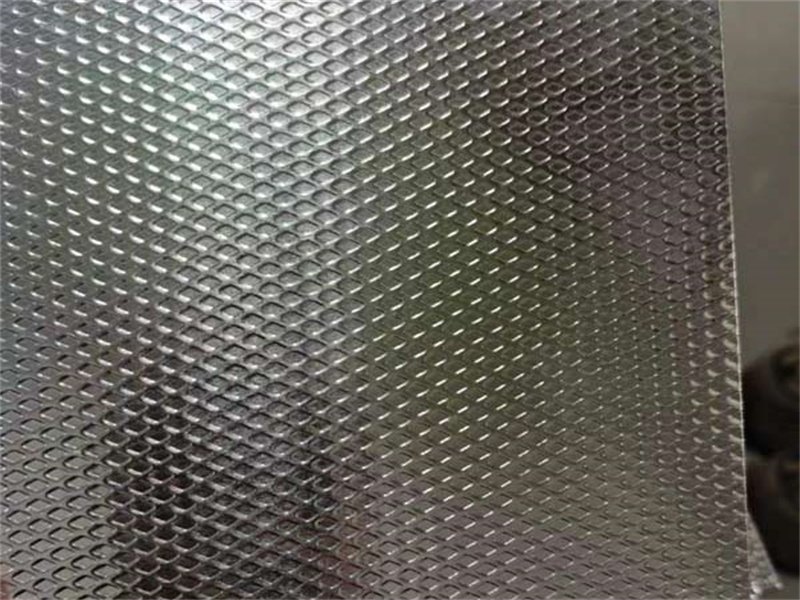

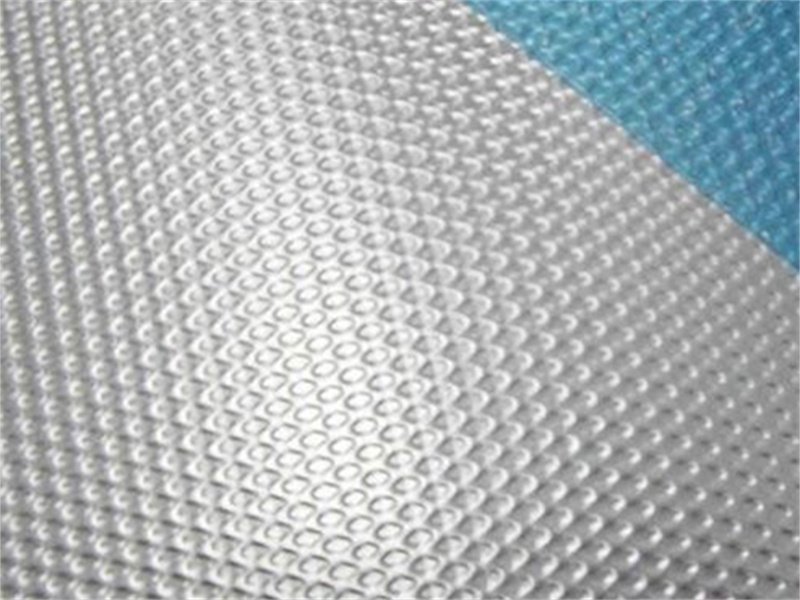

Aluminum embossed sheet is a lightweight, durable, and decorative material widely used in construction, refrigeration, transportation, and industrial projects. The embossed surface provides an anti-slip texture and attractive appearance. It is also resistant to corrosion, making it a popular choice for indoor and outdoor applications.

Aluminum embossed sheets are categorized based on their surface patterns and manufacturing processes. These decorative metal sheets feature raised or recessed designs created through mechanical pressing or rolling techniques.

| Classification Type | Pattern Style | Common Uses |

|---|---|---|

| Diamond Pattern | Raised diamond shapes | Industrial flooring, truck beds |

| Stucco Pattern | Random textured surface | Architectural panels, refrigeration |

| Five Bar Pattern | Parallel raised bars | Anti-slip applications, walkways |

| Pointer Pattern | Small raised dots | Decorative applications, signage |

| Custom Pattern | Client-specific designs | Specialized industrial needs |

The aluminum embossed sheet classification system helps manufacturers and buyers identify the right product for specific applications. Each pattern type offers unique benefits in terms of grip, aesthetics, and functionality.

Thickness specifications for aluminum embossed sheets vary significantly based on intended use and structural requirements.

| Thickness Range | Measurement (mm) | Measurement (inches) | Typical Applications |

|---|---|---|---|

| Ultra-thin | 0.2 – 0.5 | 0.008 – 0.020 | Decorative panels, packaging |

| Standard | 0.5 – 2.0 | 0.020 – 0.079 | General construction, signage |

| Medium | 2.0 – 4.0 | 0.079 – 0.157 | Industrial equipment, flooring |

| Heavy-duty | 4.0 – 6.0 | 0.157 – 0.236 | Heavy machinery, truck beds |

| Extra-heavy | 6.0+ | 0.236+ | Specialized industrial applications |

Choosing the correct aluminum embossed sheet thickness ensures optimal performance and cost-effectiveness for your project requirements.

Different aluminum alloys provide varying properties for embossed sheet applications.

| Alloy Series | Primary Composition | Key Properties | Best Applications |

|---|---|---|---|

| 1xxx Series | 99%+ Pure Aluminum | Excellent corrosion resistance | Food industry, chemical equipment |

| 3xxx Series | Aluminum-Manganese | Good formability, moderate strength | General sheet metal work |

| 5xxx Series | Aluminum-Magnesium | High strength, marine grade | Marine applications, architectural |

| 6xxx Series | Aluminum-Magnesium-Silicon | Heat treatable, structural | Construction, automotive |

Aluminum embossed sheet alloy selection directly impacts performance characteristics such as strength, corrosion resistance, and workability.

Proper packaging protects aluminum embossed sheets during transportation and storage.

| Package Type | Sheet Quantity | Protection Method | Shipping Weight |

|---|---|---|---|

| Wooden Crates | 50-100 sheets | Foam padding, moisture barrier | 500-2000 kg |

| Steel Pallets | 20-50 sheets | Plastic wrapping, corner guards | 200-800 kg |

| Custom Boxes | 10-25 sheets | Individual wrapping, cushioning | 100-400 kg |

| Bulk Packaging | 100+ sheets | Waterproof covers, separation layers | 1000+ kg |

Quality aluminum embossed sheet packaging prevents scratching, denting, and environmental damage during transit.

| Treatment Type | Process | Benefits | Cost Factor |

|---|---|---|---|

| Mill Finish | No additional treatment | Natural aluminum appearance | Low |

| Anodized | Electrochemical oxidation | Enhanced corrosion resistance | Medium |

| Painted | Powder or liquid coating | Color options, weather protection | Medium-High |

| Polished | Mechanical surface finishing | High reflectivity, premium look | High |

| Parameter | Metric Range | Imperial Range | Tolerance |

|---|---|---|---|

| Width | 1000-2000 mm | 39-79 inches | ±2 mm |

| Length | 2000-6000 mm | 79-236 inches | ±3 mm |

| Thickness | 0.2-10 mm | 0.008-0.394 inches | ±0.05 mm |

Aluminum embossed sheet applications span multiple industries:

• Manufacturing equipment covers and panels

• Anti-slip flooring for factories and warehouses

• Heat exchangers and cooling systems

• Transportation vehicle components

• Safety barriers and protective guards

• Building facade cladding and decorative panels

• Interior wall coverings and ceiling tiles

• Stair treads and walkway surfaces

• Elevator interiors and public spaces

• Roofing and siding materials

• Refrigeration equipment and cold storage

• Kitchen equipment and food service areas

• Retail display fixtures and signage

• Marine vessel interiors and exteriors

• Automotive trim and body panels

| Standard | Scope | Testing Requirements |

|---|---|---|

| ASTM B209 | Aluminum sheet specifications | Chemical composition, mechanical properties |

| ISO 6892 | Tensile testing methods | Yield strength, elongation, hardness |

| ASTM B117 | Salt spray corrosion testing | Corrosion resistance evaluation |

| EN 485 | European aluminum standards | Dimensional tolerances, surface quality |

Proper maintenance extends the lifespan of aluminum embossed sheet installations:

• Use mild detergent solutions for regular cleaning

• Avoid abrasive materials that may damage the embossed pattern

• Apply protective wax for enhanced appearance retention

• Schedule periodic professional inspections

• Store sheets in dry, ventilated areas

• Use protective coverings to prevent scratching

• Maintain proper stacking with separating materials

• Monitor for signs of corrosion or damage

Aluminum embossed sheet products offer versatile solutions for industrial, architectural, and commercial applications. Understanding the classification system, thickness options, alloy specifications, and packaging requirements helps ensure successful project outcomes. Whether you need anti-slip flooring, decorative panels, or industrial equipment covers, selecting the appropriate aluminum embossed sheet specifications is crucial for optimal performance and longevity.

The combination of durability, aesthetics, and functionality makes aluminum embossed sheets an excellent choice for demanding applications across various industries.

Q1: What is the standard size of aluminum embossed sheet?

A: Common sizes include 4×8 ft (1220x2440mm) and custom sizes are available.

Q2: Can embossed aluminum sheet be used outdoors?

A: Yes, it is resistant to weather and corrosion, suitable for outdoor use.

Q3: Which alloy is best for marine applications?

A: Alloy 5052 embossed sheet is highly recommended due to its corrosion resistance in marine environments.

Q4: What thickness is best for flooring?

A: For heavy-duty flooring, 3.0mm – 6.0mm thickness is most suitable.