Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

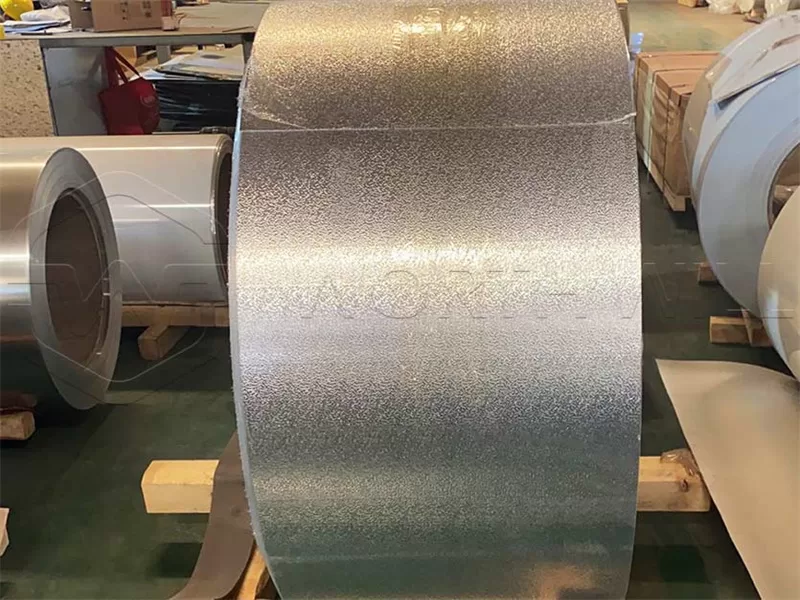

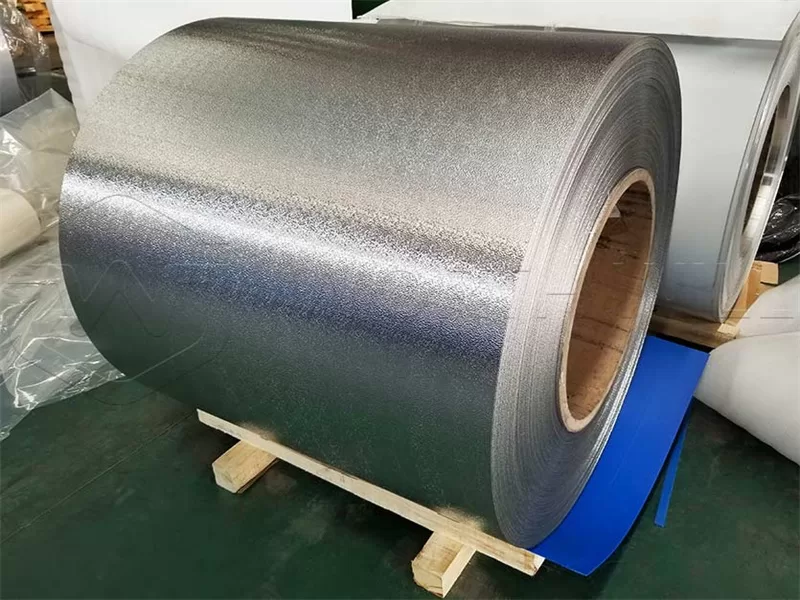

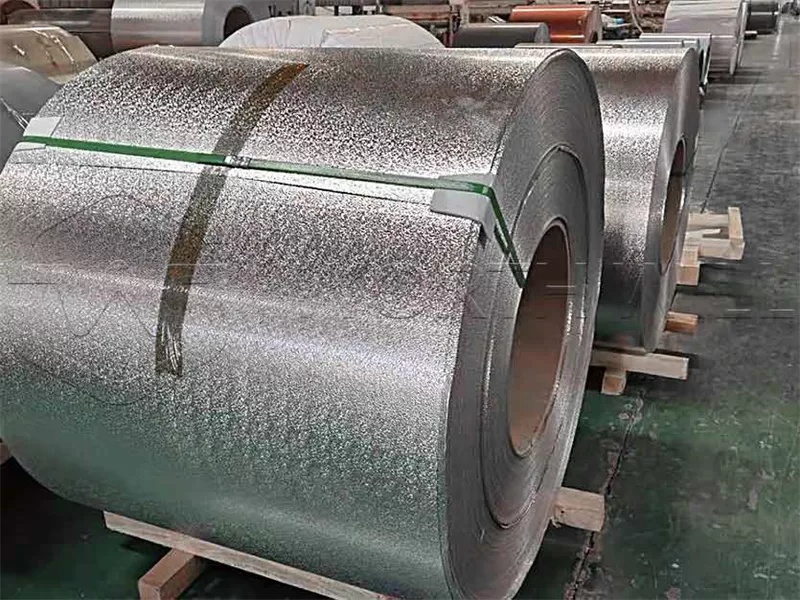

When sourced from China, these coils often combine competitive pricing with high-quality production standards, making China embossed aluminium coil a popular choice for various industries worldwide. Among its many forms, china embossed aluminum coil stands out for its unique textured surface, which offers both aesthetic appeal and practical benefits.

China embossed aluminium coil can be classified based on its surface pattern and any additional surface treatments.

| Classification Type | Details |

|---|---|

| By Embossing Pattern | |

| Stucco Embossed | Resembles plaster or orange peel; excellent for hiding minor imperfections, widely used for insulation and decorative purposes. |

| Diamond Embossed | Distinct diamond or checker plate pattern; primarily used for anti-slip flooring in various applications. |

| Five-Bar Embossed | Similar to diamond plate but with five raised bars; popular for anti-slip flooring and vehicle interiors. |

| Orange Peel Embossed | Finer, more subtle texture than stucco; often used in refrigeration and appliance industries. |

| By Surface Treatment | |

| Mill Finish | Coil is simply embossed without further surface treatment, retaining natural aluminum look. |

| Color Coated | A layer of paint (PE, PVDF) is applied, offering a wide range of colors and enhanced corrosion resistance. Popular for decorative uses. |

| Anodized | Electrochemically treated surface creates a thicker, more durable, and corrosion-resistant oxide layer, also available in various colors. |

The thickness of embossed aluminium coil is a critical specification influencing its application, strength, and overall weight. China embossed aluminum coil is available in a wide range to suit diverse project requirements.

| Thickness Range (mm) | Typical Imperial (Inches) | Characteristics & Common Uses | Common Alloys |

|---|---|---|---|

| 0.2mm – 0.5mm | 0.008″ – 0.020″ | Thin, flexible, and lightweight. Ideal for insulation jacketing, HVAC ductwork, and lightweight decorative panels. | 1050 aluminum coil, 1060, 1100 |

| 0.5mm – 1.2mm | 0.020″ – 0.047″ | Medium gauge, balance of strength and formability. Suitable for refrigerator liners, certain building material cladding, general fabrication. | 3003 aluminum coil, 3004, 3105, some 1xxx |

| 1.2mm – 2.0mm+ | 0.047″ – 0.079″+ | Thicker, more rigid, and highly durable. Used for heavy-duty applications like anti-slip flooring, toolboxes, and robust decorative panels. | 5052 aluminum coil, 3003, 5754 |

Choosing the correct aluminum coil thickness is essential for ensuring the performance and longevity of the final product.

The specific aluminum alloy used determines the mechanical properties of the embossed aluminum coil, including its strength, formability, and corrosion resistance. Chinese aluminum coil manufacturers offer coils in various standard alloy grades.

| Alloy Series | Common Alloys | Characteristics | Typical Embossed Uses |

|---|---|---|---|

| 1000 Series (Pure Al) | 1050, 1060, 1100 | Excellent formability, high corrosion resistance, good thermal/electrical conductivity. Relatively soft. | Insulation jacketing (stucco embossed), decorative applications, fin stock. |

| 3000 Series (Al-Mn) | 3003, 3004, 3105 | Moderate strength, good workability, excellent corrosion resistance. Stronger than 1000 series but highly formable. | Refrigeration units, air conditioning systems, roofing, wall panels, HVAC ductwork. 3003 aluminum coil is very popular. |

| 5000 Series (Al-Mg) | 5052, 5754 | Higher strength than 1000/3000 series, excellent corrosion resistance, especially in marine environments. | Anti-slip flooring, marine applications, truck body panels, toolboxes. 5052 aluminum coil is a strong choice. |

China has emerged as a leading supplier of embossed aluminum coil for several compelling reasons:

The production of embossed aluminum coil involves several precise steps:

Proper aluminum coil packaging is crucial for protecting the material during transit, especially for international shipping. China aluminum coil suppliers typically employ robust methods.

| Packaging Component | Purpose |

|---|---|

| Inner Core Protection | Sturdy paper or plastic core to maintain coil shape and prevent collapse. |

| Moisture-Proof Wrapping | Waterproof paper, plastic film, or desiccant bags to protect against humidity and oxidation. |

| Edge Protection | Cardboard or plastic corner protectors applied to edges to prevent damage during handling. |

| Securing | Steel or strong plastic bands to prevent unraveling or shifting of the coil. |

| Wooden Pallets/Skids | Fumigated wooden platforms for easy forklift handling and stable stacking. |

| Orientation | “Eye-to-Sky” (vertical) or “Eye-to-Wall” (horizontal) depending on size and weight for stable transport. |

| Wooden Cases/Crates | (Optional) For maximum protection during long-distance or overseas shipping. |

The unique properties of embossed aluminum coil offer numerous advantages:

| Benefit | Description |

|---|---|

| Enhanced Aesthetics | Textured surface adds visual depth and a modern, appealing look, making it a popular decorative panel material. |

| Increased Strength & Rigidity | Embossing hardens the surface and increases structural integrity, making it more resistant to bending and denting. |

| Improved Heat Dissipation | Increased surface area aids in radiating heat more efficiently, beneficial in refrigeration and HVAC applications. |

| Anti-Slip Properties | Patterns like diamond plate provide excellent traction, ideal for anti-slip flooring and treads. |

| Corrosion Resistance | Aluminum’s natural resistance to rust and corrosion is maintained, often enhanced by protective coatings. |

| Lightweight Nature | Remains lightweight despite added strength, simplifying transportation and installation. |

| Durability & Low Maintenance | Textured surface effectively hides minor scratches and smudges, contributing to longevity and requiring less maintenance. |

The versatility of China embossed aluminum coil allows its use across a wide array of industries and applications:

| Industry | Typical Applications |

|---|---|

| Building & Construction | Insulation Jacketing (pipes, tanks, ducts), Roofing and Siding, Decorative Panels (walls, ceilings), Door Skins, Window Frames. |

| Refrigeration & HVAC | Refrigerator and Freezer Liners, Air Conditioner Fin Stock, Ductwork Fabrication. |

| Transportation | Trailer and RV Siding, Bus and Train Interior Panels, Tool Boxes, Truck Bed Liners (anti-slip flooring). |

| General Industrial & Consumer Goods | Solar Panel Backing, Street Lighting Fixtures, Appliance Components, Furniture Components. |

Embossed aluminum coil is an aluminum sheet that has been passed through rollers with a raised pattern, creating a textured design on its surface. This process, known as embossing, doesn’t just add a decorative look; it also enhances the material’s properties. The textured surface increases the material’s rigidity and strength, making it less prone to denting and scratching. It also improves heat dissipation and can provide an anti-slip surface, depending on the pattern. Common patterns include stucco embossed, diamond embossed, five-bar (checker plate), and orange peel.

China is one of the largest exporters of embossed aluminum coil, offering:

With advanced production lines and strict quality control, suppliers like WORTHWILL ALUMINUM ensure stable quality and custom solutions.

At WORTHWILL ALUMINUM, embossed aluminum coils are packed securely to prevent surface damage.

Customized branding and labels are also available.

Ordering embossed aluminum coil from China is simple:

Contact WORTHWILL ALUMINUM for free consultation and personalized support.

China embossed aluminum coil is a remarkable material that combines the inherent benefits of aluminum with enhanced properties derived from the embossing process. Its diverse applications, ranging from building material and insulation to refrigeration and transportation, underscore its versatility and value. With a wide array of thicknesses, alloy grades, and patterns available from reputable Chinese suppliers, finding the perfect embossed aluminum coil for any project is easier than ever. By offering a compelling blend of aesthetic appeal, durability, and cost-effectiveness, China embossed aluminum coil continues to be a top choice for manufacturers and builders worldwide.