Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

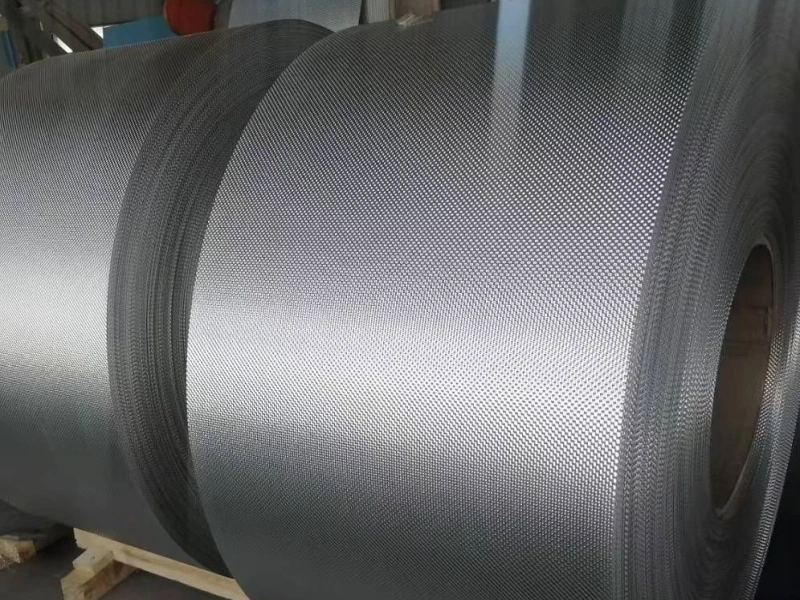

In many industries, controlling heat is crucial for safety, performance, and equipment longevity. This is where the embossed aluminum heat shield plays a vital role. These specialized shields are engineered to provide excellent thermal management, protecting sensitive components from high temperatures and radiant heat. They are a lightweight, durable, and highly effective solution for various challenging environments.

| Feature | Description |

|---|---|

| Material | Aluminum alloy (1100, 3003, 5052, 8011) |

| Thickness | 0.1 mm – 1.5 mm |

| Embossing Types | Diamond, ripple, orange peel |

| Surface Finish | Mill finish, anodized, coated |

| Tempers | O, H14, H24 |

| Width Range | 600 mm – 1300 mm |

| Coil or Sheet | Available in both formats |

Customized dimensions and coatings are available based on project needs.

Embossed aluminum heat shields are popular for their:

Cost-effective solution – Affordable yet high performance

High thermal reflectivity – Reflects radiant heat efficiently

Lightweight structure – Easy to install without adding weight

Corrosion resistance – Suitable for outdoor and engine environments

Increased strength – Embossed patterns add rigidity without more thickness

Easy to form and cut – Compatible with stamping, folding, and trimming

Embossed aluminum heat shields can be classified in several ways, often based on their design and intended use. Common types include:

Each classification offers unique advantages depending on the thermal challenge and space constraints of the application. The choice often depends on the level of thermal protection required and the environmental conditions.

The thickness of an embossed aluminum heat shield is a critical specification that directly impacts its performance and structural integrity. Common thicknesses range from very thin foils for lightweight, flexible applications to thicker sheets for more rigid, structural heat barriers.

The appropriate thickness depends on the specific thermal load, the required lifespan of the shield, and any physical stresses it might endure.

The alloy of aluminum used for the heat shield significantly affects its properties, including its thermal performance, corrosion resistance, and formability. Common aluminum alloys used for embossed aluminum heat shields include:

The selection of the alloy is crucial for ensuring the embossed aluminum heat shield performs reliably over its lifespan, especially when exposed to harsh conditions or specific chemical environments.

Our state-of-the-art production facility ensures:

Consistent quality through automated processes

Quick response times with streamlined operations

Custom solutions with in-house engineering

Strict quality control at every production stage

| Feature | Our Products | Industry Standard |

|---|---|---|

| Temperature Range | Up to 650°F | Typically 500°F |

| Corrosion Resistance | Excellent | Good |

| Customization Options | Extensive | Limited |

| Lead Time | 2-3 weeks | 4-6 weeks |

| Price Competitiveness | 15-20% better value | Standard pricing |

Automotive Supplier in Germany

Reduced engine bay temperatures by 22% with our custom heat shield solution.

Aerospace Manufacturer in USA

Trusts our aerospace-grade shields for critical thermal protection.

Industrial Plant in China

Improved equipment lifespan by 30% with our heavy-duty heat shields.

We’re committed to providing:

Contact our team now to discuss your specific requirements!

Embossed aluminum heat shields offer a host of advantages that make them a preferred solution for thermal management across diverse sectors. Their unique design contributes significantly to their superior performance.

One of the primary benefits is their exceptional ability to reflect radiant heat. Aluminum is naturally highly reflective, and the embossed surface enhances this property by increasing the total surface area. This reflective capability is a cornerstone of effective thermal protection.

Aluminum is renowned for its low density, making embossed aluminum heat shields incredibly lightweight. This is a significant advantage in applications where weight reduction is crucial, such as in the automotive and aerospace industries. A lighter heat shield contributes to overall vehicle or aircraft efficiency without compromising on thermal performance.

The inherent properties of aluminum, especially when combined with specific alloys, provide excellent durability and corrosion resistance. Embossed aluminum heat shields can withstand harsh environmental conditions, including exposure to moisture, chemicals, and varying temperatures, ensuring a long service life. This robustness makes them a reliable long-term investment.

Aluminum is a highly ductile metal, allowing embossed aluminum heat shields to be easily formed and shaped to fit complex contours and tight spaces. The embossing process itself adds rigidity, making the material stiffer than flat aluminum of the same thickness, yet it retains enough flexibility for custom fabrication. This formability is essential for creating custom-fit solutions that maximize thermal efficiency.

Compared to other high-performance thermal insulation materials, embossed aluminum heat shields offer a very cost-effective solution. Their long lifespan, low maintenance requirements, and efficient manufacturing processes contribute to a lower total cost of ownership, making them an economically sound choice for businesses.

The versatility and effectiveness of embossed aluminum heat shields make them indispensable in a wide array of applications where managing heat is paramount.

The effectiveness of an embossed aluminum heat shield lies in its design and material properties. When radiant heat strikes the polished or reflective surface of the aluminum, a significant portion of that energy is reflected away, rather than being absorbed. This is due to aluminum’s high emissivity.

The “embossed” pattern, typically a dimpled or corrugated surface, plays a dual role:

By reflecting radiant heat and creating insulating air gaps, these shields efficiently manage thermal energy, keeping protected areas cooler and safer.

Selecting the ideal embossed aluminum heat shield requires careful consideration of several factors to ensure optimal performance and longevity.

By assessing these factors, you can select an embossed aluminum heat shield that perfectly aligns with your specific application requirements, ensuring effective and long-lasting thermal protection.

The embossed aluminum heat shield is an essential component in modern thermal management strategies. Its unique combination of excellent heat reflection, lightweight design, durability, and versatility makes it an indispensable solution across countless industries. From safeguarding sensitive electronics in automotive engines to ensuring critical temperature control in industrial machinery, these shields deliver reliable thermal protection. Choosing the right specifications and understanding their benefits ensures optimal performance and contributes to the longevity and efficiency of various systems. For effective and efficient heat management, the embossed aluminum heat shield remains a top-tier choice.