Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

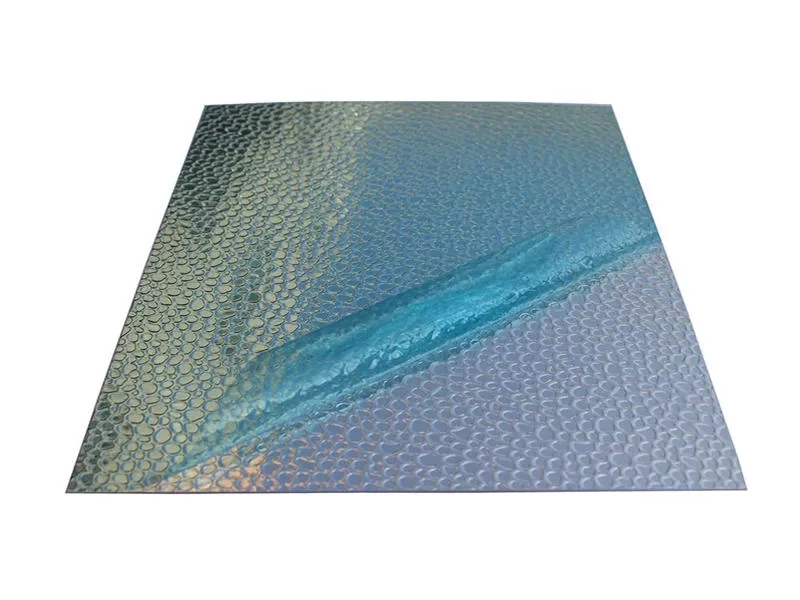

Hammered embossed aluminum is a type of aluminum sheet that has a textured surface resembling hammered metal. It combines aesthetic appeal with functionality, making it ideal for both decorative and industrial applications. This page explains its specifications, classifications, uses, and FAQs to help you understand and choose the right type.

| Property | Description |

|---|---|

| Classification | Decorative, Industrial, Architectural |

| Thickness | 0.2mm – 3.0mm |

| Surface Finish | Hammered, Embossed, Anti-fingerprint optional |

| Alloy Options | 1100, 3003, 5052, 8011 |

| Width Range | 500mm – 1600mm |

| Length | Customized or in coil form |

| Packaging | Export-worthy wooden pallets, protective film |

| Type | Pattern Depth | Visual Effect | Common Applications |

|---|---|---|---|

| Light Hammered | 0.1-0.3mm | Subtle texture | Elevator interiors, furniture |

| Medium Hammered | 0.3-0.6mm | Distinct pattern | Wall cladding, ceilings |

| Deep Hammered | 0.6-1.2mm | Dramatic 3D effect | Feature walls, art installations |

| Custom Hammered | Variable | Bespoke designs | Luxury retail spaces |

Hammered embossed aluminum is available in various thicknesses to suit different applications:

| Thickness (mm) | Weight (kg/m²) | Recommended Uses |

|---|---|---|

| 0.4-0.6 | 1.08-1.62 | Decorative panels, signage |

| 0.8-1.0 | 2.16-2.70 | Furniture, interior partitions |

| 1.2-1.5 | 3.24-4.05 | Architectural facades |

| 2.0-3.0 | 5.40-8.10 | Structural applications |

Different aluminum alloys provide varying performance characteristics:

| Alloy Series | Key Properties | Best For |

|---|---|---|

| 1000 (1050, 1060) | Excellent formability | Decorative hammered effects |

| 3000 (3003, 3004) | Good strength, weldable | Architectural applications |

| 5000 (5052, 5083) | Superior corrosion resistance | Marine environments |

| 6000 (6061, 6063) | High structural integrity | Load-bearing elements |

Hammered embossed aluminum is an aluminum sheet that has been with a hammered pattern using a mechanical embossing process. The surface has a dimpled appearance, which improves visual appeal and enhances surface strength. It has wide applciations in wall panels, ceilings, backsplashes, signs, and decorative panels.

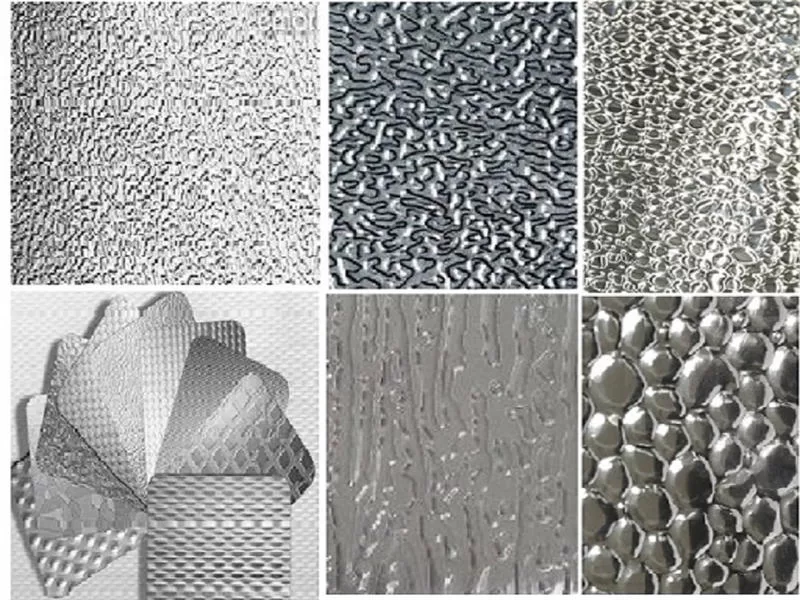

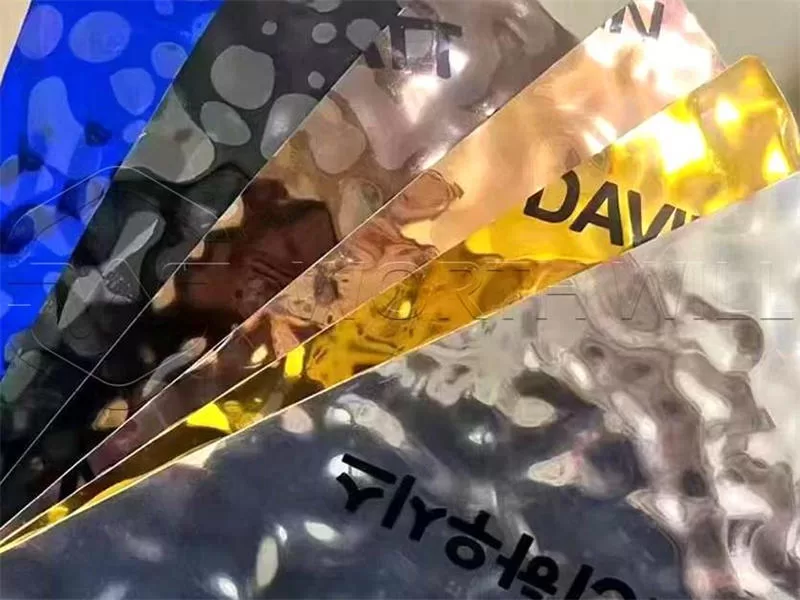

You can choose different hammered aluminum types based on thickness, alloy, and finish. Here are the most common types available:

| Type | Alloy | Thickness | Surface Finish |

|---|---|---|---|

| Decorative Hammered Sheet | 1100/3003 | 0.3–1.5mm | Bright/Mirror |

| Industrial Hammered Coil | 8011/5052 | 0.5–2.0mm | Matt Embossed |

| Anti-corrosion Hammered Coil | 5052 | 1.0–3.0mm | Coated or Lacquered |

Hammered aluminum is used in many industries thanks to its decorative texture and resistance to wear. Key applications include:

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength | 100-310 MPa | ASTM B209 |

| Yield Strength | 35-276 MPa | ASTM B209 |

| Elongation | 3-30% | ASTM B557 |

| Hardness | 25-95 HB | ASTM E10 |

Hammered aluminum is a metal that has been shaped or textured to create small indentations, giving it a dimpled, handcrafted appearance. In modern production, this is done by machines through embossing.

Embossed aluminum refers to any aluminum sheet that has a textured or raised pattern on its surface. “Hammered” is one type of embossed finish.

Hammered aluminum became especially popular in the 1920s to 1940s in kitchenware and decorative items.

Yes. Apart from its decorative and functional use, vintage hammered aluminum items may have collectible value. Modern sheets are also valued for architecture and interior design.

At its core, hammered embossed aluminum is a type of aluminum sheet or coil that has undergone a mechanical process called embossing. This process creates a raised and depressed pattern on the material’s surface, giving it a three-dimensional texture.

What is embossed aluminum?

Embossed aluminum, in general, refers to aluminum that has any kind of raised pattern on its surface. This can include stucco, diamond plate, orange peel, or, as discussed here, the hammered pattern. The embossing process enhances rigidity, diffuses light, and can help to hide minor surface imperfections or scratches.

What is hammered aluminum?

While in a broader sense “hammered aluminum” can refer to vintage decorative items that were literally hammered by hand, in the context of modern industrial production, it refers to aluminum that has been mechanically embossed with a “hammered” pattern. This industrial process allows for consistent texture over large areas, suitable for manufacturing and construction.

If you’re looking for hammered embossed aluminum coil suppliers or want to customize a pattern or finish, contact us today. We offer cut-to-size sheets, bulk rolls, and custom embossing for your unique needs.

📧 Email: [jane@wwaluminum.com ]

📞 WhatsApp: [+8615736973771 ]

Selecting a trustworthy hammered embossed aluminum supplier is paramount to ensuring the success of your project. Consider the following factors: