Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

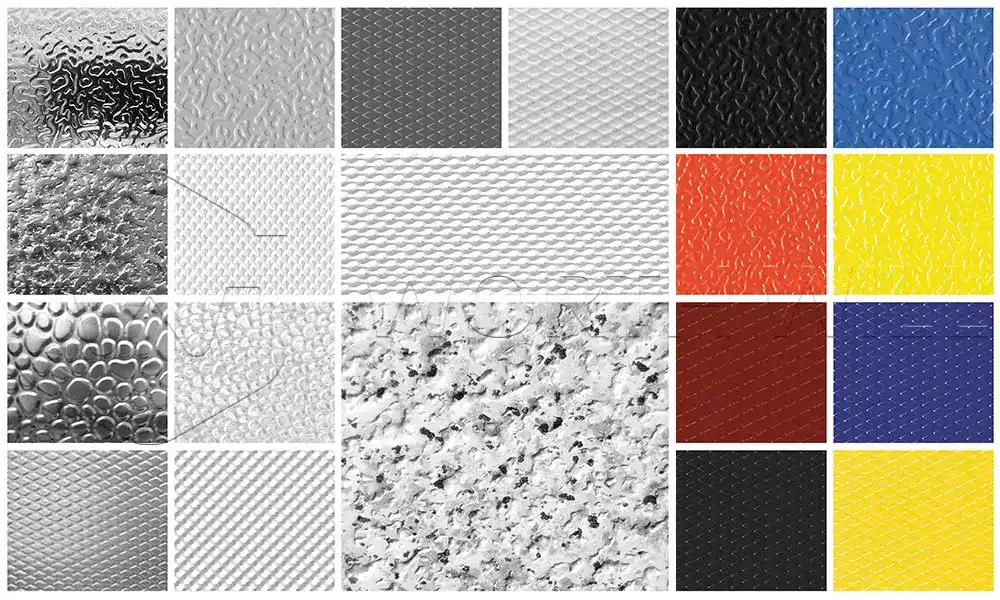

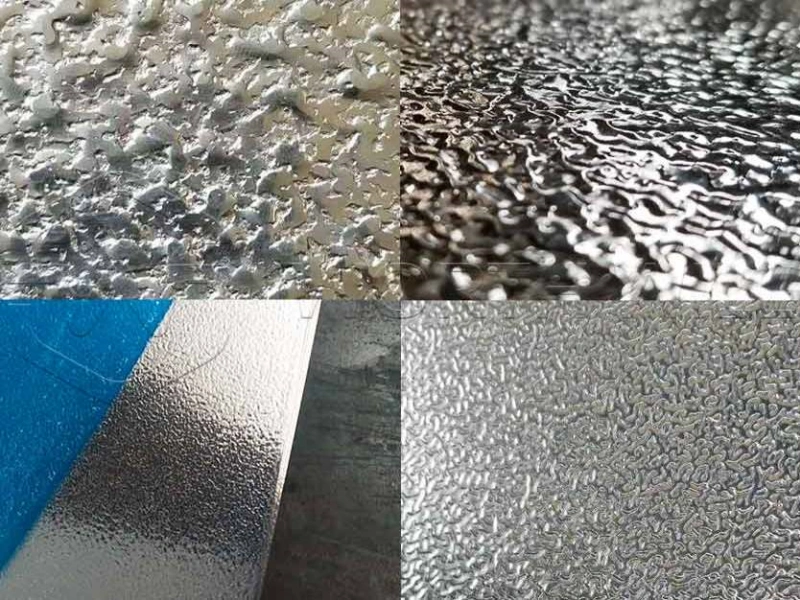

Patterned and embossed aluminum plate is widely used decorative and functional metal materials. These plates have raised or textured surfaces created by rolling or pressing. The designs improve appearance and offer practical benefits like anti-slip properties, easy cleaning, and enhanced durability.

Worthwill Aluminum is a professional manufacturer of embossed aluminum plates in China, offering custom patterns, thicknesses, and surface treatments to meet your project needs.

| Item | Detail |

|---|---|

| Alloy | 1050, 1060, 1100, 3003, 5052, etc. |

| Temper | H14, H24, H18, H32 |

| Thickness | 0.2 mm – 6.0 mm |

| Width | 300 mm – 1500 mm |

| Length | Customized or standard length (1000–6000 mm) |

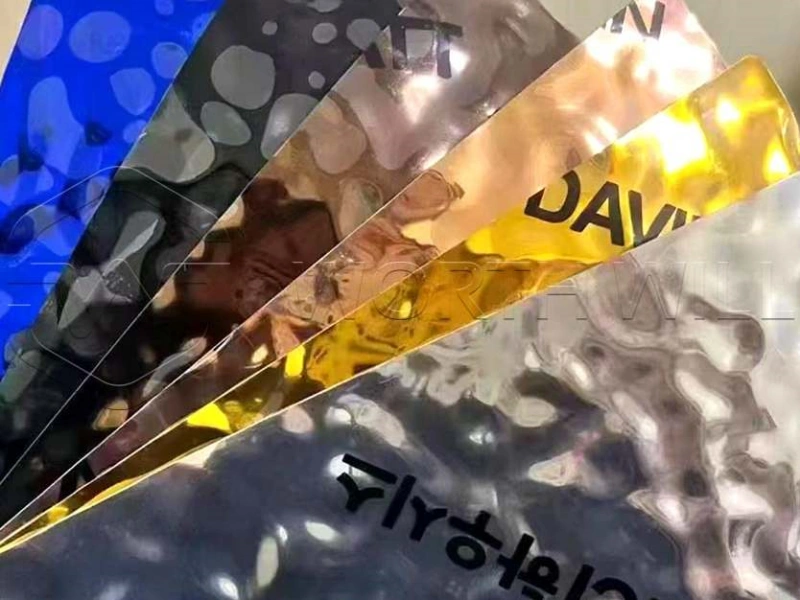

| Surface Finish | Mill finish, anodized, color coated |

| Patterns | Diamond, Orange Peel, Stucco, 5 Bar, etc. |

Patterned and embossed aluminum plates are available in different styles:

Each pattern has its unique look and function.

Patterned and Embossed Aluminum Plate: A Comprehensive Guide

Aluminum is a fantastic metal, known for being lightweight and strong. But when you add patterns or embossed designs, it becomes even more special. Patterned aluminum plate and embossed aluminum plate are unique types of aluminum sheets. They are not just flat and plain; they have raised textures or beautiful designs. This makes them perfect for many uses, from tough industrial floors to stylish decorative walls.

These special aluminum plates offer many benefits. They are durable, look great, and can be used almost anywhere. If you are looking for a material that combines strength, good looks, and long life, then patterned and embossed aluminum is an excellent choice.

What is Patterned Aluminum Plate?

Patterned aluminum plate refers to aluminum sheets with a raised, regular design on one side. These patterns are created during the manufacturing process, usually by rolling the aluminum through special machines. The most common types you might see are:

The main reason for these patterns is to create grip. They make the surface non-slip, which is very important for safety. They also add strength and can hide scratches and dirt, making the surface look clean for longer. This makes patterned aluminum sheet a very practical material.

What is Embossed Aluminum Plate?

Embossed aluminum plate is similar to patterned aluminum, but it often focuses more on decorative elements or specific textures that might not be uniform across the entire sheet. Embossed aluminum sheet has a design that is pressed into or raised from its surface. This process uses special dies or rollers to create intricate designs, logos, or even simple textures.

While patterned aluminum usually has a repeated, functional pattern, embossed aluminum can have a wider variety of designs. The embossing process can make the aluminum sheet stiffer and improve its strength without adding much weight. It also creates a very attractive surface that can reflect light in interesting ways. This makes decorative aluminum plate highly valued for its visual appeal.

Key Features and Advantages

Both patterned and embossed aluminum plates share many great qualities that make them popular in many industries:

Common Applications of Patterned and Embossed Aluminum Plate

The unique properties of these aluminum plates make them useful in a wide range of areas:

Choosing the Right Patterned or Embossed Aluminum Plate

When you decide to use patterned aluminum plate or embossed aluminum plate for your project, there are a few important things to consider:

Always choose a reputable aluminum plate supplier to ensure you get high-quality material that meets your needs.

Embossed aluminum refers to aluminum that has a raised or textured pattern on its surface. This pattern is created by passing the aluminum sheet through rollers with designs, such as stucco, diamond, or orange peel. The embossing improves appearance, adds strength, and creates anti-slip properties. It is widely used in decorative panels, flooring, refrigerators, and insulation.

The main difference is thickness:

In general:

The most commonly used aluminum plate materials include:

Like all materials, aluminum plates may have some defects if not properly processed or handled. Common defects include:

At Worthwill Aluminum, we perform strict quality control to avoid these issues and deliver defect-free products.

Conclusion

Patterned and embossed aluminum plate are more than just sheets of metal. They are versatile, durable, and attractive materials that bring both function and style to countless applications. From ensuring safety on industrial walkways with diamond plate aluminum to adding a touch of modern elegance with decorative aluminum panels in architecture, their uses are widespread. Their combination of strength, light weight, and aesthetic appeal makes them a smart choice for anyone looking for a reliable and good-looking material. Consider these excellent aluminum options for your next project.