Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

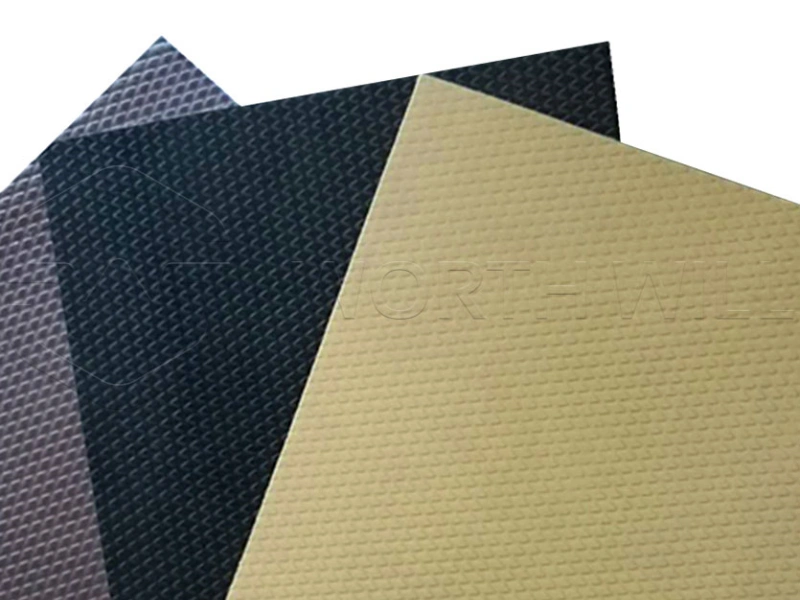

Looking for a reliable stucco embossed aluminum factory? Whether for insulation, decoration, or industrial protection, stucco embossed aluminum is a trusted material known for its durability, anti-corrosion features, and attractive finish.

At Worthwill Aluminum, we offer a full range of stucco embossed aluminum sheets, coils, and jacketing products, directly from our factory—customized to meet your needs.

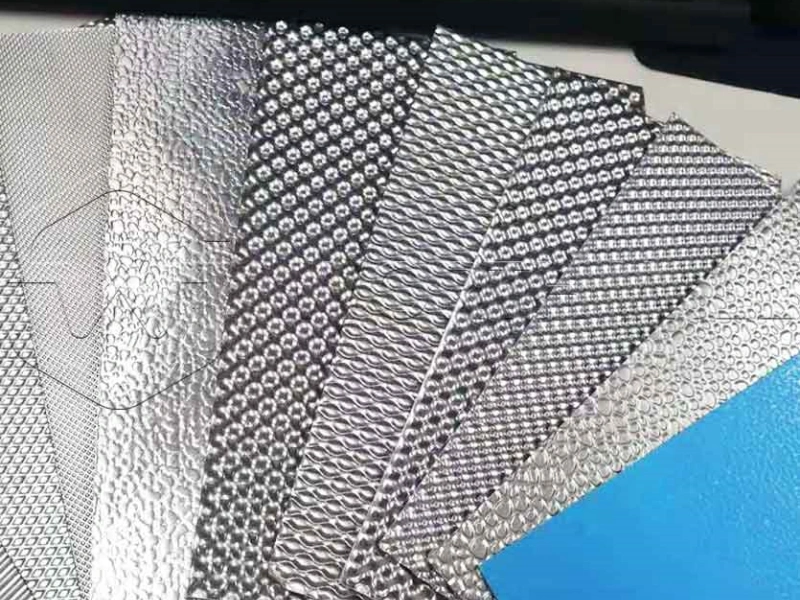

Stucco embossed aluminum can be classified by alloy, thickness, finish, and application:

Each type offers specific advantages for different industrial and architectural uses.

This type features a kraft paper moisture barrier on the back, which protects insulation from water vapor. It’s commonly used in:

Benefits:

As a leading stucco embossed aluminum manufacturer, our factory provides:

Our products meet international standards and are exported worldwide.

Aluminum jacketing with a stucco embossed finish is used to cover insulation systems for:

Features:

Available with moisture barriers such as poly-kraft paper or polysurlyn film for enhanced protection.

Combining anti-slip properties with a decorative finish, stucco aluminum tread plates are often applications in:

Embossed texture provides grip while resisting scratches and corrosion.

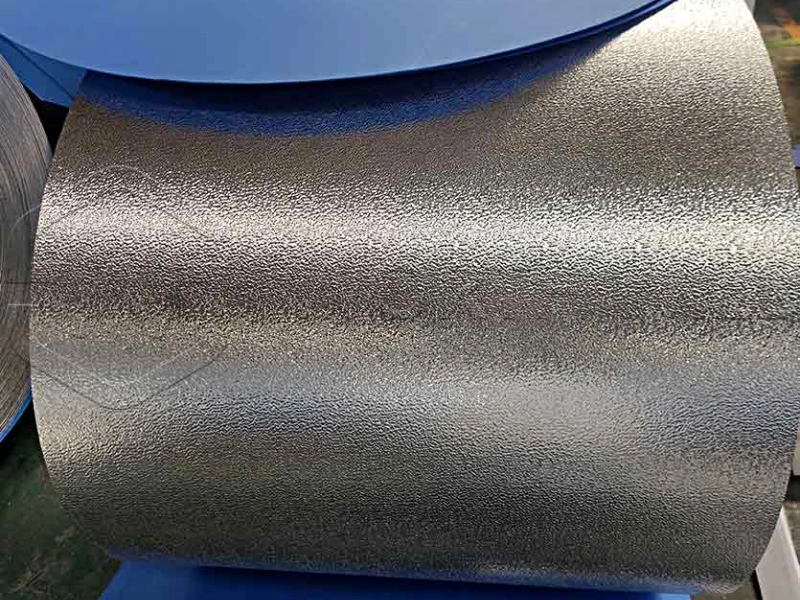

We supply stucco embossed aluminum in both sheet and coil forms. Sheet sizes are available in standard or custom dimensions, while coils are ideal for continuous production lines.

Common Sizes:

Packing:

Different alloys offer specific performance features:

Our team will help you choose the best alloy for your project.

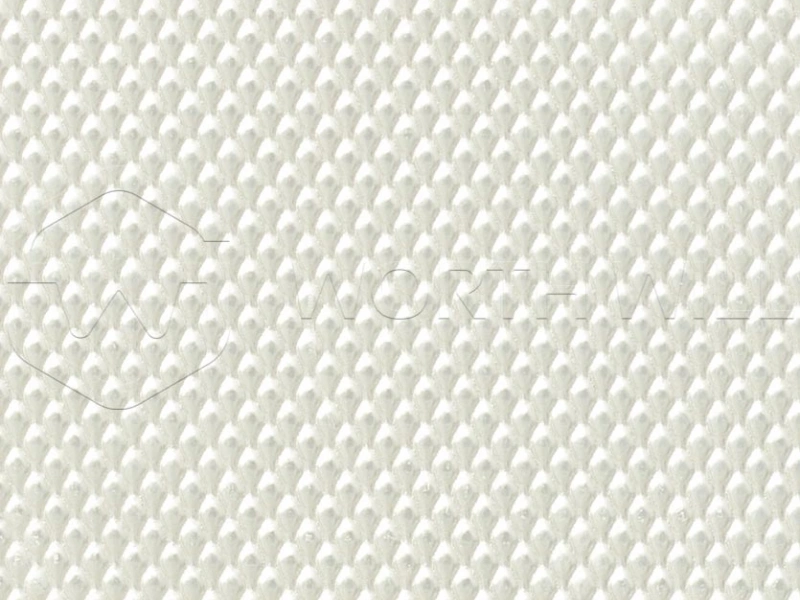

“Stucco embossed” refers to the irregular, textured surface of the aluminum sheet. The pattern resembles the rough appearance of stucco plaster, which:

The embossed pattern is created through a roller process that presses the design onto the surface.

Embossed aluminum is a type of aluminum sheet that has been processed to create a raised or patterned surface. This not only improves the sheet’s appearance but also:

It’s widely used in construction, insulation, vehicle body panels, and interior decoration.

Traditional stucco is not commonly applied over aluminum. However, stucco embossed aluminum offers the look of stucco without actual plaster, providing a decorative and maintenance-free alternative.

For real stucco finishes, proper bonding materials and preparation would be needed—but in most cases, embossed aluminum is the preferred, cost-effective option.

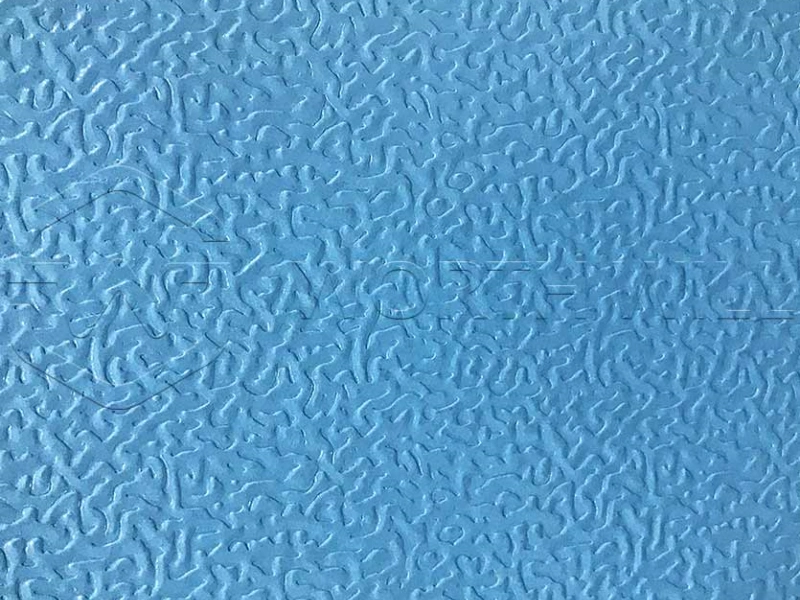

Stucco aluminum is simply aluminum with a stucco-embossed finish. It’s especially popular for cladding systems, pipe insulation, and architectural panels.

This versatile material is used across many industries:

When it comes to specialized metal solutions, stucco embossed aluminum stands out for its unique texture, durability, and wide range of applications. This distinctive aluminum product, created by a specialized stucco embossed aluminum factory, offers a rough, orange-peel-like finish that is not only visually appealing but also highly functional. It’s an excellent choice for industries needing a material that combines strength, lightness, and a non-reflective surface.

The term “stucco embossed” refers to a specific manufacturing process that gives aluminum sheets a textured surface. Imagine the look of traditional stucco plaster – that slightly rough, uneven finish. Stucco embossed aluminum mimics this appearance. The metal sheet is passed through rollers that imprint a random, non-directional pattern onto its surface. This process is different from simply painting or coating the metal; the texture is physically part of the aluminum itself.

More broadly, embossed aluminum is any aluminum sheet or coil that has a pattern or design pressed into its surface. This can range from geometric shapes to decorative patterns, or in the case of “stucco embossed,” a specific irregular texture. The embossing process not only adds aesthetic value but can also increase the material’s rigidity, improve grip, and reduce light reflectivity, making it highly versatile for many uses.

Stucco embossed aluminum offers several key advantages that make it a preferred material in various sectors:

Leading stucco embossed aluminum factories utilize advanced rolling mills and precise tooling to create these specialized sheets and coils. The manufacturing process ensures a consistent texture and high-quality finish across large batches. Reputable manufacturers focus on maintaining strict quality control, ensuring that each sheet meets industry standards for alloy composition, temper, and dimensional accuracy. Working directly with a stucco embossed aluminum factory allows for custom orders, competitive pricing, and reliable supply.

Stucco embossed aluminum is primarily available in two forms: sheets and coils.

A common product offered by many stucco embossed aluminum manufacturers is stucco embossed aluminum sheet with kraft paper backing. This paper layer serves several important purposes:

This combination is particularly useful in HVAC ducting and pipe insulation jacketing.

Stucco embossed aluminum can be produced from various aluminum alloys. Each offering different properties suited for specific applications. Common alloy types include:

The choice of alloy depends on the required strength, corrosion resistance, formability, and intended use of the final product.

One of the most significant applications for stucco embossed aluminum is in jacketing or cladding for insulation. This includes:

The textured surface of stucco embossed aluminum jacketing also helps to reduce condensation and control noise.

While less common than diamond plate for heavy-duty anti-slip uses, stucco embossed aluminum can also be in lighter-duty tread plate applications. Its textured surface provides some increased friction, making it suitable for:

The pattern helps to conceal scuffs and scratches, maintaining a cleaner appearance over time.

The versatility of stucco embossed aluminum allows it to be classified and used across a wide range of industries:

It’s important to clarify a common misunderstanding: stucco embossed aluminum is an aluminum product that looks like stucco. You generally cannot apply traditional stucco plaster directly over aluminum as a building finish. Stucco needs a porous surface to bond properly, and aluminum is a non-porous metal. If you wanted a stucco-like finish on an aluminum structure, you would typically need to prepare the surface with specialized primers and bonding agents, or use panels that mimic the stucco look. The term “stucco aluminum” itself refers to the embossed aluminum product, not aluminum that has been covered with stucco.

Partnering with a dedicated stucco embossed aluminum factory ensures you receive a product tailored to your exact needs. These factories possess the specialized machinery and expertise to consistently produce high-quality textured aluminum sheets and coils. They can offer:

Stucco embossed aluminum is a remarkable material that combines the inherent benefits of aluminum with a unique, functional texture. From its aesthetic appeal and enhanced durability to its superior performance in insulation and anti-slip applications, it’s a versatile solution for numerous industries. By understanding what is stucco embossed aluminum and sourcing from a reputable stucco embossed aluminum factory, businesses can unlock its full potential for their projects, ensuring long-lasting, high-performing results.

If you’re sourcing stucco embossed aluminum sheet or coil, we’re here to help. As a direct factory, we offer high-quality products, competitive prices, and reliable service.

📧 Email: jane@wwaluminum.com

📱 WhatsApp: +8615736973771

Request a quote today—let us be your trusted aluminum partner.