Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

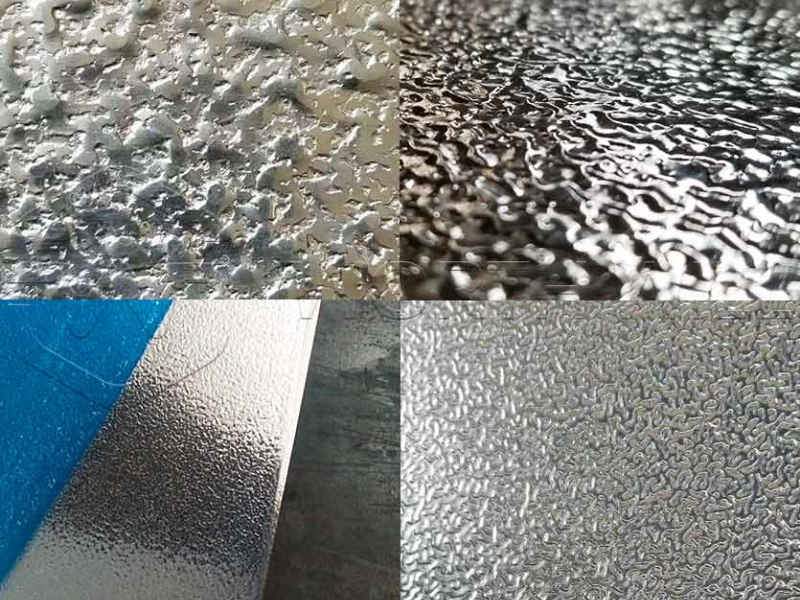

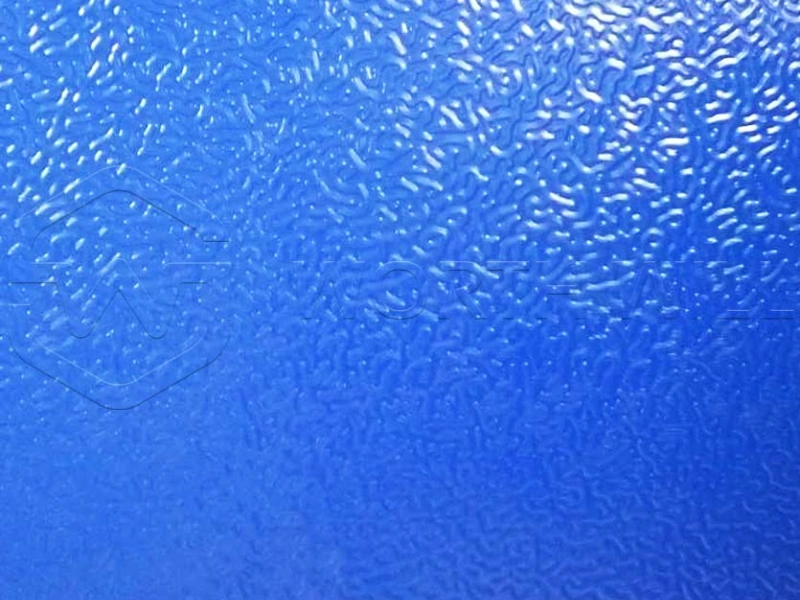

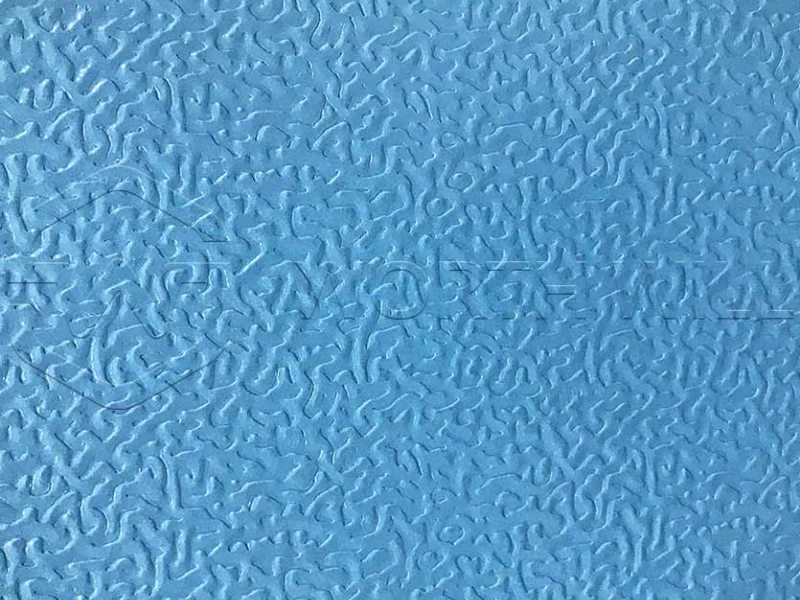

Stucco embossed aluminum is one of the most popular materials for cold room construction. Its textured surface provides durability, corrosion resistance, and an attractive look while maintaining excellent thermal efficiency. With lightweight properties, high strength, and easy maintenance, it is widely used for walls, ceilings, and doors of cold rooms in food storage, pharmaceuticals, and logistics.

Stucco embossed aluminum can be classified by alloy type and usage:

| Type | Description |

|---|---|

| 1100 Stucco Embossed | Excellent corrosion resistance, indoor applications |

| 3003 Stucco Embossed | Lightweight and durable, widely used in cold storage |

| 3105 Stucco Embossed | Good outdoor performance, industrial projects |

| 5052 Stucco Embossed | Superior moisture resistance, marine environments |

Different thicknesses are available depending on cold room design:

| Thickness (mm) | Application |

|---|---|

| 0.3 – 0.5 | Interior wall panels, ceiling panels |

| 0.6 – 0.8 | Cold room doors, medium-size storage areas |

| 1.0 – 1.2 | Industrial cold storage walls and partitions |

| 1.5 – 2.0 | Exterior cladding, heavy-duty cold rooms |

Stucco embossed aluminum is available in multiple alloys:

To keep the sheets safe during transport and storage:

Stucco embossed aluminum is widely used in:

| Parameter | Details |

|---|---|

| Thickness | 0.3 – 2.0 mm |

| Width | 600 – 1500 mm |

| Alloys | 1100, 3003, 3105, 5052 |

| Surface Finish | Stucco embossed (matte or glossy) |

| Packaging | PE film, wooden pallets, waterproof wrapping |

| Applications | Cold storage, refrigeration, industrial cladding |

Installing stucco embossed aluminum in your cold room is straightforward, contributing to quicker project completion.

Due to its lightweight nature and ease of fabrication, stucco embossed aluminum sheets can be cut, bent, and fastened with relative ease. This reduces labor time and installation costs for cold storage construction.

Maintaining hygiene in a cold room is paramount. The non-porous surface of aluminum, combined with the stucco texture, makes it easy to wipe clean. Regular cleaning with mild detergents ensures the cold room remains sanitary and visually appealing.

Investing in stucco embossed aluminum for cold room facilities offers tangible benefits for businesses.

While the initial cost might be slightly higher than some alternatives, the long-term cost savings are significant. Its durability reduces the need for frequent repairs or replacements, and its contribution to thermal efficiency lowers energy bills.

The reflective properties and contribution to insulation mean less energy is required to maintain desired temperatures in the cold room. This translates directly to lower operational costs and a smaller carbon footprint.

Choosing a material that is resistant to corrosion, durable, and easy to maintain ensures that your cold room remains functional and efficient for many years. This makes stucco embossed aluminum a smart, long-term investment for any business requiring reliable cold storage.

1. Why is stucco embossed aluminum better than plain aluminum for cold rooms?

Because the embossed surface makes it stronger, more durable, and reduces scratches during installation.

2. What thickness is most common for cold room panels?

Most projects use 0.6 mm to 0.8 mm thick aluminum sheets.

3. Can it be used in humid or coastal environments?

Yes. For better performance, 3003 or 5052 alloys are recommended.

4. Is it available in both sheets and coils?

Yes. Large cold room projects often use coils, while small repairs use sheets.