Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the vast world of metals, aluminum stands out for its lightweight nature, durability, and excellent corrosion resistance. But what if you need an aluminium sheet that’s not just functional but also visually appealing and more robust against daily wear and tear? That’s where embossed aluminium comes into play. If you’ve ever seen a metal surface with a distinct, raised pattern, chances are you’ve encountered embossed aluminium. It’s a highly versatile material that combines the inherent benefits of aluminum with enhanced aesthetics and improved performance.

So, what exactly is embossed aluminium? Simply put, it’s a flat aluminium sheet that has undergone a mechanical process to create a raised, patterned surface. This isn’t a coating or a print; it’s a physical alteration of the metal itself. This unique texture makes embossed aluminium much more than just a decorative material; it adds significant practical advantages, making it a popular choice across numerous industries.

| Alloy | Strength | Corrosion Resistance | Formability | Typical Use |

|---|---|---|---|---|

| 1100 | Low | Excellent | Excellent | Decorative panels, signs |

| 3003 | Medium | Very good | Excellent | Roofing, insulation |

| 5052 | High | Excellent | Good | Marine, transport |

| 5754 | High | Excellent | Good | Flooring, heavy-duty use |

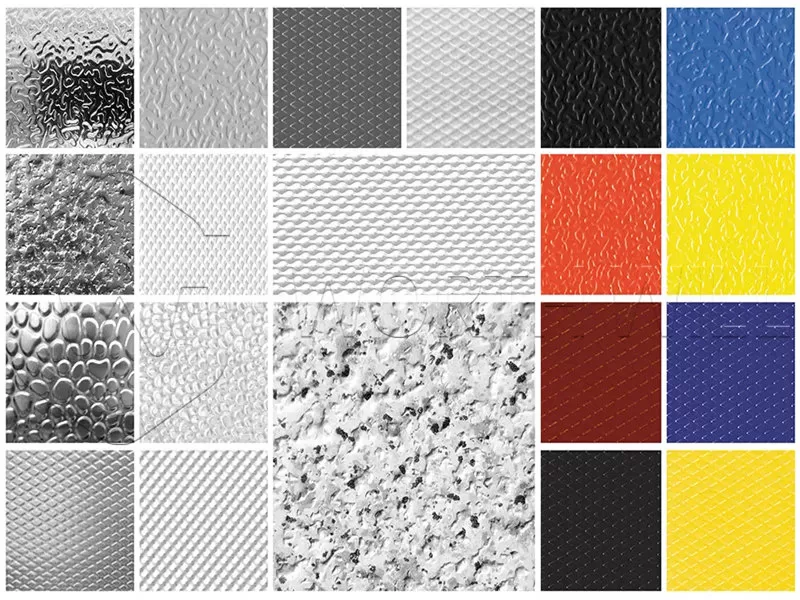

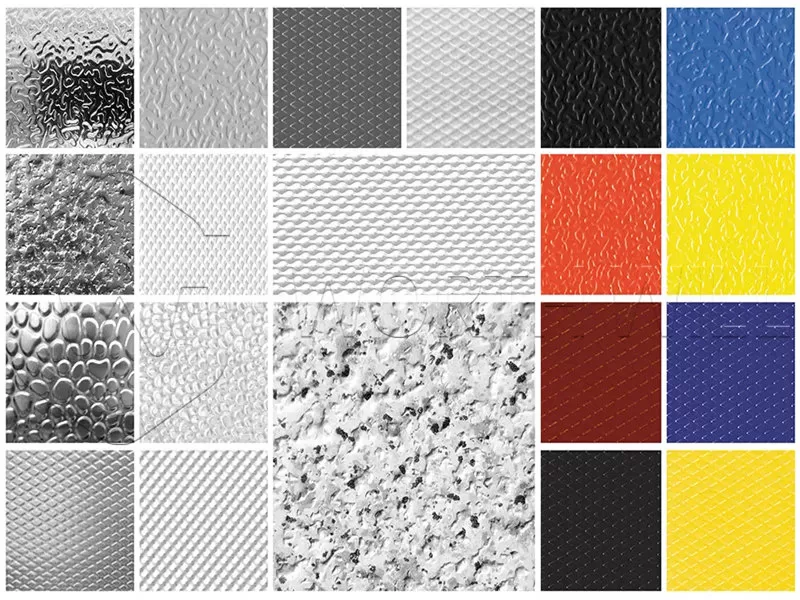

Embossed aluminium comes in several popular patterns, each with its unique characteristics and ideal applications.

| Pattern Type | Description | Typical Applications | Key Benefits |

|---|---|---|---|

| Stucco Embossed Aluminium | Features a dimpled, non-directional pattern resembling an orange peel. It’s the most common type. | Refrigerators, freezers, cold rooms, HVAC ducting, insulation jacketing, trailer skins, decorative panels. | Hides scratches, diffuses light, anti-glare, good aesthetic. |

| Diamond Plate / Checker Plate / Tread Plate Aluminium | Characterized by raised diamond or bar patterns arranged in a repeating sequence. Designed for grip. | Flooring, ramps, stair treads, truck beds, toolboxes, loading docks, fire trucks, decorative elements. | Excellent anti-slip properties, high durability, industrial aesthetic. |

| Pebbled / Grain Embossed Aluminium | Features small, irregular raised bumps (pebbled) or fine, linear lines (grain). Often subtle. | Decorative panels, interior architectural finishes, appliance parts, furniture accents. | Subtle aesthetic, hides minor imperfections, adds texture. |

| Brushed Embossed Aluminium | Combines a directional brushed finish with an embossed pattern, creating a layered visual effect. | High-end appliances, decorative trims, architectural accents. | Sophisticated aesthetic, still benefits from pattern hiding minor marks. |

| Other Custom Patterns | Manufacturers can create bespoke patterns for unique branding or design requirements. | Custom architectural features, branded signage, unique product casings. | Exclusive aesthetics, brand identity, unique product differentiation. |

When selecting embossed aluminium, you’ll also consider standard aluminum specifications:

The creation of embossed aluminium is a fascinating process known as metal embossing. It involves passing a plain aluminium sheet through a pair of specially designed rollers. These rollers have matching male and female dies (or a single engraved roller against a smooth one) that press the desired pattern onto the metal surface. As the sheet passes through, the pressure from the rollers permanently changes the surface, creating the raised (embossed) and recessed (debossed) areas that form the pattern.

This process transforms a smooth, often reflective, aluminium sheet into a textured one. The pattern can be simple or intricate, uniform or random, depending on the design of the rollers. Because the pattern is mechanically pressed into the metal, it’s incredibly durable and will not peel, chip, or fade over time, unlike a painted or coated finish. This inherent durability is one of the main reasons why industries choose embossed aluminium.

Embossed aluminium inherits all the natural benefits of regular aluminum, such as being lightweight, non-corrosive, and recyclable. However, the embossing process adds several distinct characteristics:

These combined properties make embossed aluminium a highly practical and aesthetically pleasing choice for a wide array of applications.

Choosing embossed aluminium for your project brings a multitude of advantages:

These benefits demonstrate why embossed aluminium is increasingly preferred for applications demanding both functionality and aesthetics.

The unique combination of properties makes embossed aluminium suitable for a wide array of applications across various sectors:

Embossed aluminium is a truly remarkable material that takes the inherent advantages of aluminum and elevates them with added texture and functionality. From hiding scratches and diffusing light to providing anti-slip properties and enhancing aesthetic appeal, this textured aluminium sheet offers practical solutions for a vast range of industrial, architectural, and consumer applications. As industries continue to seek lightweight, durable, and visually appealing materials, embossed aluminium stands out as a smart, versatile, and increasingly popular choice, proving its value in both form and function.