Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

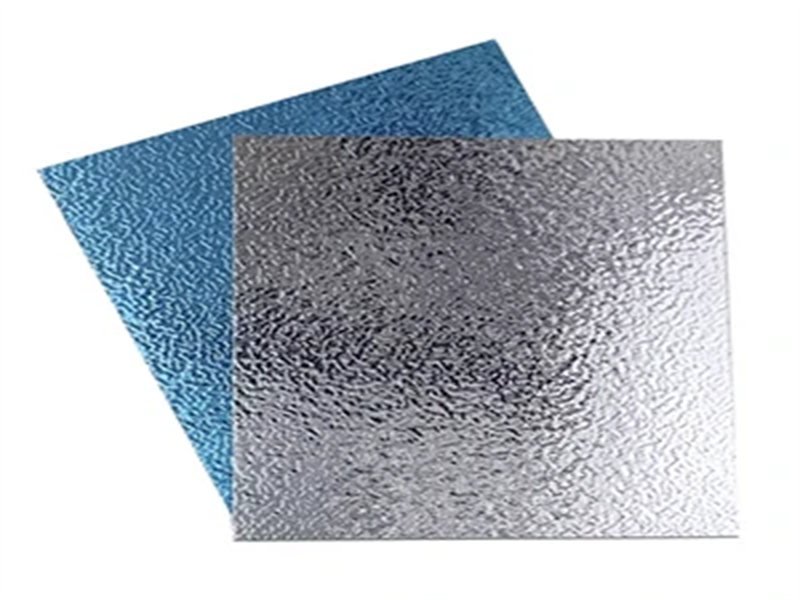

Embossed aluminium foil is a special type of aluminium foil that has a raised design or pattern pressed into its surface. Unlike smooth, plain foil, the embossing process gives it a distinctive texture. This process creates a three-dimensional effect, which not only looks appealing but also enhances the foil’s performance in many ways. From improving grip to increasing its strength, embossed aluminium foil stands out in various applications. It’s a versatile material found in many industries, providing both functional benefits and aesthetic value.

| Parameter | Details |

|---|---|

| Alloy | 8011, 3003, 1235 |

| Temper | O, H22, H24 |

| Thickness | 0.03 mm – 0.2 mm |

| Width | 200 mm – 1500 mm |

| Surface Pattern | Stucco embossed, diamond embossed |

| Coating | Mill finish, color coated |

| Packaging | Wooden cases, pallet packaging, waterproof paper |

The creation of embossed aluminium foil involves a precise mechanical process. High-quality aluminium foil rolls are fed through a pair of rollers, one of which has the desired pattern engraved onto its surface. As the foil passes between these rollers, the design is pressed and transferred onto the foil, creating the raised or depressed areas. This embossing process permanently alters the foil’s surface, giving it its characteristic texture. Different patterns can be created, from simple dots and lines to more complex decorative designs, tailoring the foil for specific needs.

Embossed aluminium foil offers several significant advantages over traditional smooth foil:

Embossed aluminium foil comes in various specifications to meet diverse application requirements. These can differ in thickness, pattern type, and temper (how hard or soft the foil is). Below is a table illustrating some common types and their typical characteristics:

| Feature | Description | Common Specifications / Examples |

|---|---|---|

| Thickness | Measured in micrometers (µm) or mils, impacts durability. | 10 µm (0.4 mil) – 200 µm (8 mil) |

| Pattern Type | The design pressed onto the surface. | Diamond, Stucco, Pin Dot, Grid, Custom |

| Alloy Temper | How soft (annealed) or hard (tempered) the foil is. | O (Soft), H14 (Half-hard), H18 (Full-hard) |

| Width | The width of the foil roll. | 50 mm – 1500 mm |

| Surface Finish | Additional treatments or coatings. | Bright, Dull, Lacquered, Coated |

Example Specifications:

The unique properties of embossed aluminium foil make it suitable for a wide range of uses across many industries:

Choosing embossed aluminium foil means opting for a material that combines the inherent benefits of aluminum foil with enhanced features. Its unique texture provides practical advantages like improved strength, better grip, and sometimes even improved insulation. Beyond functionality, the aesthetic appeal of different patterns makes it a preferred choice for products where visual presentation is key. For manufacturers and consumers alike, embossed aluminum foil offers a superior solution, promising durability, efficiency, and a touch of sophistication. Whether for industrial use or everyday household tasks, its versatility and performance make it an intelligent choice.

From its distinct manufacturing process to its wide array of applications, its unique patterns and enhanced properties set it apart. As industries continue to seek materials that offer both functionality and aesthetic value, embossed aluminum foil will undoubtedly remain a crucial component in diverse fields, consistently proving its worth through its strength, durability, and visual appeal. Understanding what it is and its many benefits highlights why it’s such a valuable material in today’s world.