Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In industrial, commercial, and institutional settings, maintaining the efficiency and integrity of thermal insulation on pipes, vessels, and equipment is crucial. This is where high-quality protective cladding comes in. Stucco Embossed Aluminum Jacketing is one of the most widely used and effective materials for this purpose. It provides a tough, weather-resistant barrier that extends the life of the insulation and contributes to the overall safety and efficiency of systems.

This guide will explain the benefits and features of Stucco Embossed Aluminum Jacketing, covering everything from its unique finish to its technical specifications. If you are looking for reliable Aluminum Jacketing, also known as Aluminum Roll Jacketing or Aluminum Jacket Cladding, understanding the details of the stucco embossed type is essential. We will delve into what makes this material a standard choice for Metal Cladding projects and why it offers excellent protection for your insulation assets.

| Item | Details |

|---|---|

| Product | Stucco Embossed Aluminum Jacketing |

| Alloy | 3003, 3105, 5005, 6061, 6082 |

| Temper | H14, H16, H24 (Custom temper on request) |

| Standards | ASTM B209 / C1729 |

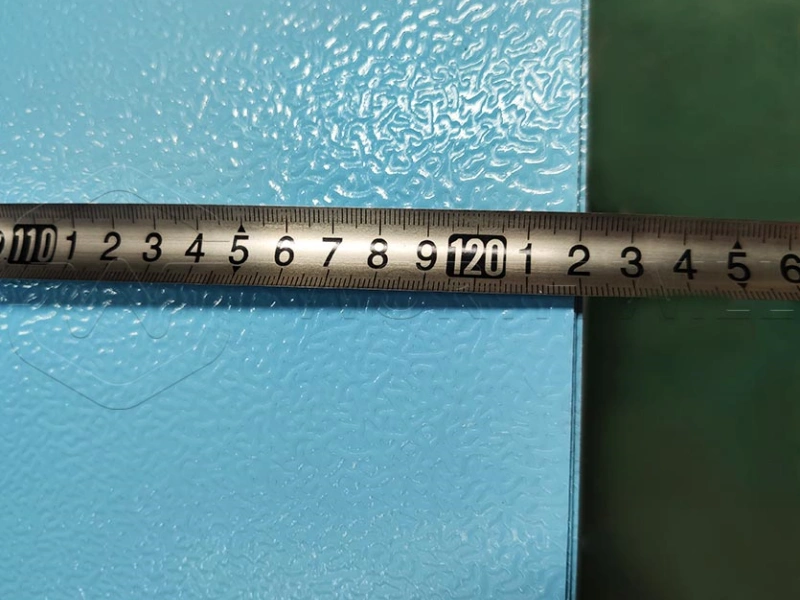

| Thickness | 0.3mm – 1.5mm |

| Width | 914mm, 1000mm, 1219mm |

| Length | 100’ (30m), 200’ (60m), Jumbo Roll |

📦 Available with Polysurlyn or Kraft Paper Moisture Barrier (PSMB/Kraft).

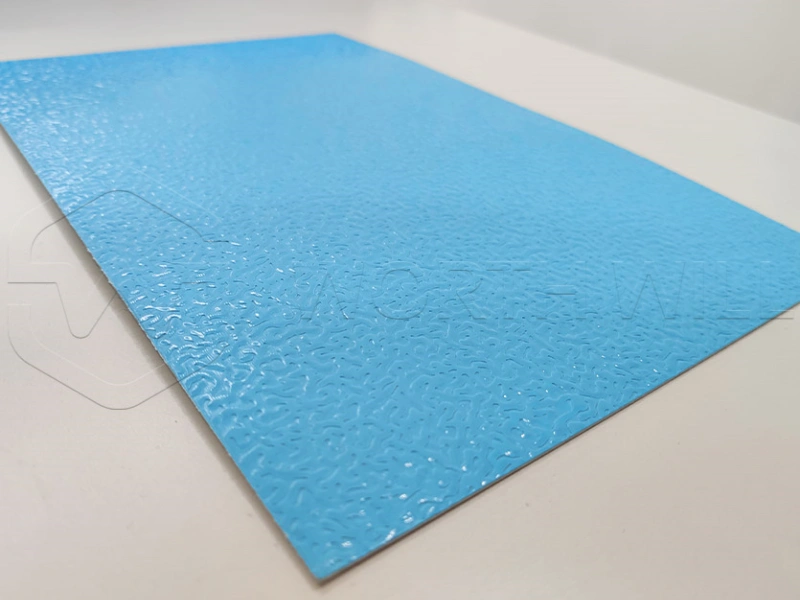

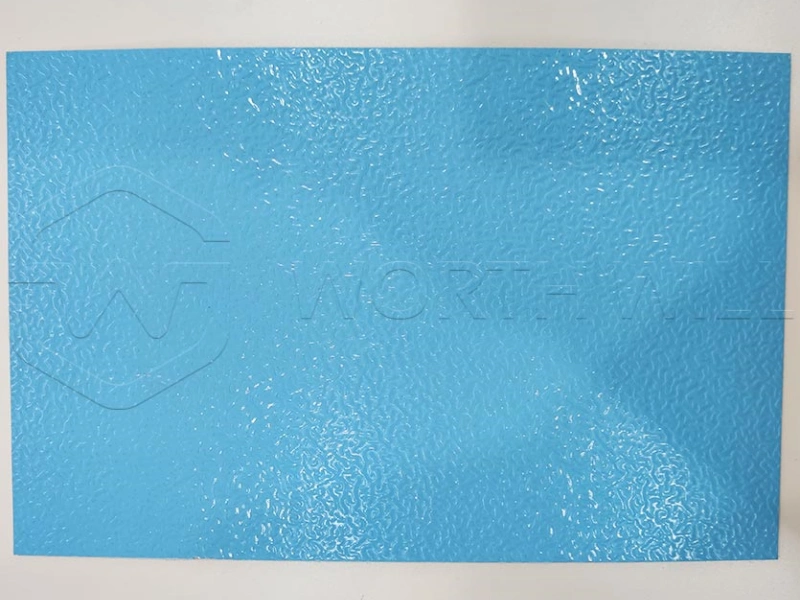

Stucco Embossed Aluminum Jacketing is a type of flat-rolled aluminum sheet or coil that has been mechanically processed to create a distinctive, non-directional pattern resembling stucco plaster. This embossed pattern is applied to the surface of the aluminum, providing both aesthetic and functional benefits. The primary purpose of this material is to serve as a protective layer (often called cladding or lagging) over thermal insulation systems on pipes, tanks, ducts, and other equipment.

Aluminum Jacketing, also referred to as Aluminum Cladding or Metal Cladding, is a protective outer layer used to shield mechanical insulation. Insulation systems are often susceptible to damage from weather (rain, UV rays, extreme temperatures), physical impact, and corrosive environments. Aluminum Jacketing forms a durable shell that protects the underlying insulation from these elements, maintaining its thermal performance and extending its lifespan. It is lightweight, easy to install, and offers excellent resistance to corrosion, particularly in atmospheric conditions. This directly answers “What is aluminium jacketing?”.

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | 96.8 – 99.0 |

| Manganese (Mn) | 1.0 – 1.5 |

| Copper (Cu) | 0.05 – 0.2 |

| Iron (Fe) | ≤ 0.7 |

| Silicon (Si) | ≤ 0.6 |

This composition ensures corrosion resistance and high strength, especially in marine and industrial environments.

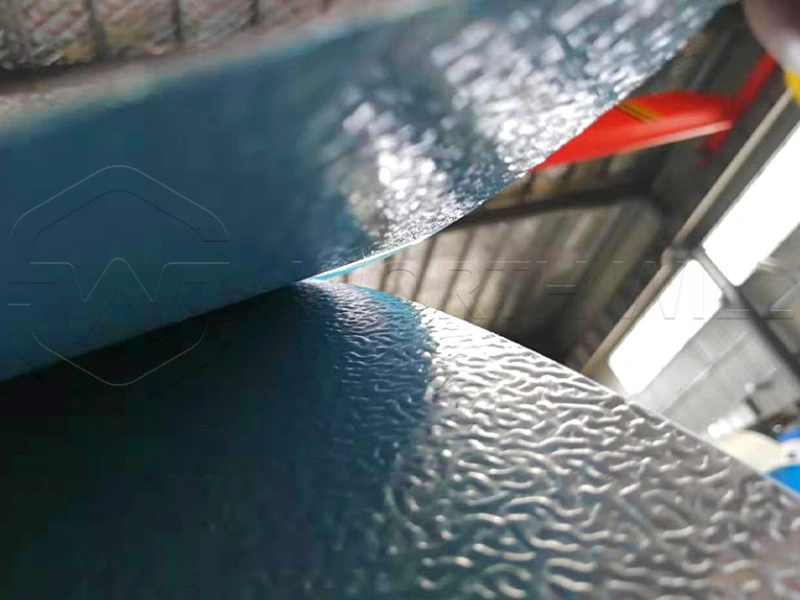

The term “stucco embossed” refers to the specific texture applied to the surface of the aluminum jacketing. It’s a mechanical process where the aluminum sheet passes through rollers with a patterned surface, pressing the design into the metal. The resulting pattern is a non-directional, irregular texture that looks similar to a traditional stucco plaster finish. This directly answers “What does stucco embossed mean?” and “What is stucco finish on aluminium?”.

Embossed aluminum is a general term for any aluminum sheet or coil that has a raised or sunken pattern pressed into its surface. Stucco embossing is just one specific type of embossed aluminum. Other common patterns include diamond plate, tread plate, or various decorative designs. The process of embossing adds rigidity to the material, making thin sheets stronger and more resistant to denting. It also provides a textured surface that can diffuse light (reducing glare) and hide minor surface imperfections that might be visible on a smooth finish. This directly answers “What is embossed aluminum?”.

In the context of Aluminum Jacketing, the stucco finish on aluminum is highly practical because it adds stiffness to the relatively thin gauge metal, makes installation easier by providing grip, reduces reflectivity (important in bright environments), and has a visually consistent, industrial appearance.

When specifying Stucco Embossed Aluminum Jacketing, it’s important to refer to established industry standards to ensure quality and performance. Our Aluminum Jacketing products are manufactured to meet these critical specifications.

| Specification Category | Details |

|---|---|

| Product | Stucco Embossed Aluminum Jacketing / Aluminum Roll Jacketing |

| Standards | ASTM B209, ASTM C1729 (Primary standards for aluminum jacketing) |

| Base Alloy | 3003 (Common base alloy for jacketing. Other available: 3105, 5005, etc.) |

| Temper | H14 (Common temper for formability & stiffness. Other tempers available) |

| Thickness | 0.3mm to 1.5mm (Common range. Often specified in inches like 0.016″, 0.024″, 0.032″) |

| Width | 914mm (approx. 36″), 1000mm, 1219mm (approx. 48″). (Other widths available) |

| Lengths | 100’ (approx. 30m), 200’ (approx. 60m), Jumbo Roll. (Often supplied as Aluminum Roll Jacketing) |

| Embossing | Stucco Embossed (Non-directional pattern) |

| Backing Options | Bare, Polysurlyn, Craft Paper, Polycraft |

These specifications are key to ordering the correct Stucco Embossed Aluminum Jacketing for your project. For example, a common size like 016 x 36″ x 100′ stucco embossed aluminum refers to a thickness of 0.016 inches (approx. 0.4mm), a width of 36 inches (approx. 914mm), and a length of 100 feet (approx. 30m) supplied as a roll of stucco embossed aluminum benicia green (though “benicia green” implies a color coating, standard jacketing is usually bare or with backing, but color options exist). The mention of 0.4mm Stucco Embossed Aluminum Jacketing with Polysurlyn highlights a specific thickness and common backing type.

Choosing Stucco Embossed Aluminum Jacketing offers a range of practical benefits for protecting industrial insulation:

Beyond the standard Stucco Embossed Aluminum Jacketing, variations are available to suit specific installation needs:

As Alloy 3003 is a common base material for Stucco Embossed Aluminum Jacketing, understanding its composition helps explain its properties. The typical chemical composition for 3003 aluminum per ASTM standards is:

| Element | Percentage (%) (Typical) |

|---|---|

| Silicon (Si) | 0.6 max |

| Iron (Fe) | 0.7 max |

| Copper (Cu) | 0.05 – 0.20 |

| Manganese (Mn) | 1.0 – 1.5 |

| Magnesium (Mg) | 0.05 max |

| Zinc (Zn) | 0.10 max |

| Other Each | 0.05 max |

| Other Total | 0.15 max |

| Aluminum (Al) | Remainder |

The controlled amount of Manganese is what gives 3003 aluminum improved strength and workability compared to pure aluminum, making it suitable for forming and embossing into durable Aluminum Jacketing.

The protective qualities and ease of installation of Stucco Embossed Aluminum Jacketing make it ideal for protecting thermal insulation in numerous industrial and commercial settings.

This Metal Cladding solution provides essential long-term protection for critical infrastructure.

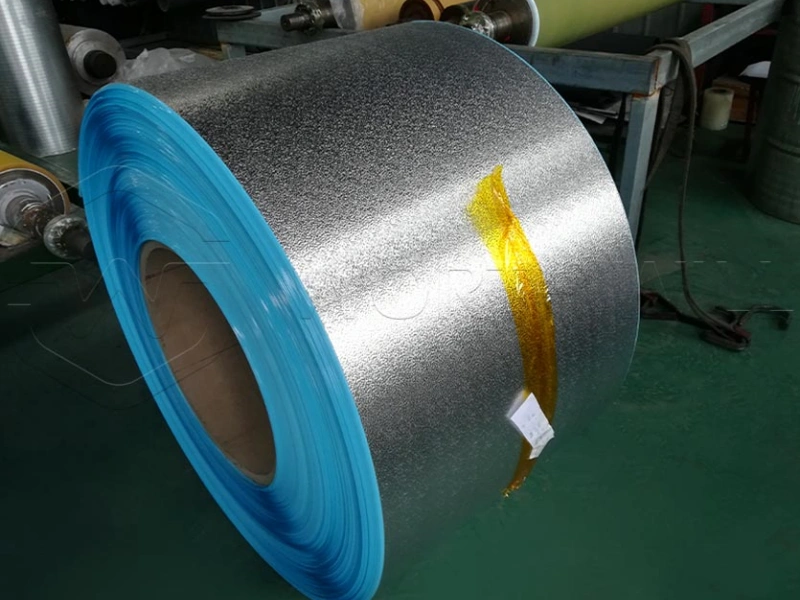

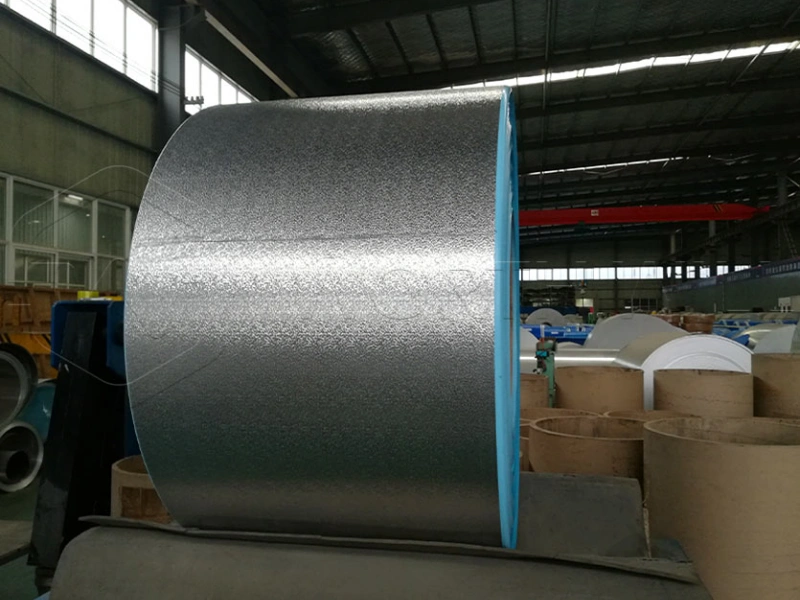

Proper packaging ensures that Stucco Embossed Aluminum Jacketing arrives at the job site in optimal condition, free from damage or moisture. Standard packaging for Aluminum Roll Jacketing typically includes:

Sheets are usually bundled, interleaved with protective paper or film, and crated on pallets. Our packaging methods are designed to protect the stucco embossed aluminum during transit.

Selecting a reliable supplier for Stucco Embossed Aluminum Jacketing is key to ensuring the quality and longevity of your insulation systems. At HENAN FASTARRIVER INDUSTRIAL CO.,LTD, we are committed to providing high-quality products that meet industry standards.

We are your trusted partner for high-quality Stucco Embossed Aluminum Jacketing, providing the protection your insulation needs.

Conclusion

Stucco Embossed Aluminum Jacketing is a proven, durable, and cost-effective solution for protecting thermal insulation on mechanical systems. Its unique stucco finish provides added rigidity, glare reduction, and a professional appearance, while the underlying aluminum, often Alloy 3003 in H14 temper conforming to ASTM B209 and ASTM C1729, offers excellent corrosion resistance.

Available in various thicknesses (like 0.4mm), widths, and lengths (as Aluminum Roll Jacketing), and with options like Polysurlyn backing, this Aluminum Jacketing is versatile for numerous applications.

If you are specifying or sourcing Stucco Embossed Aluminum Jacketing or Aluminum Cladding, choosing a supplier that adheres to standards and offers a range of options is vital. Contact HENAN FASTARRIVER INDUSTRIAL CO.,LTD today to discuss your requirements for quality stucco embossed aluminum products.

Contact Information:

HENAN FASTARRIVER INDUSTRIAL CO.,LTD

Address: Gongyi Industrial Cluster, Zhengzhou City, Henan Province, China