Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

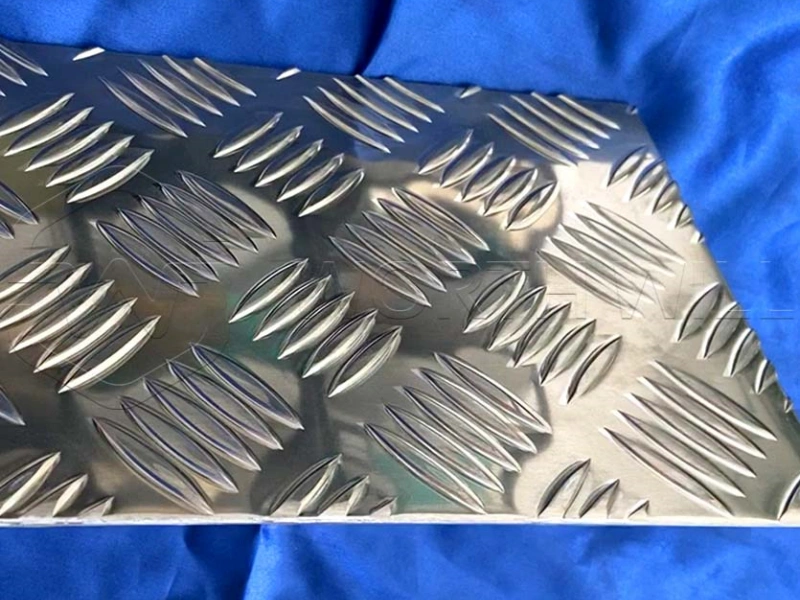

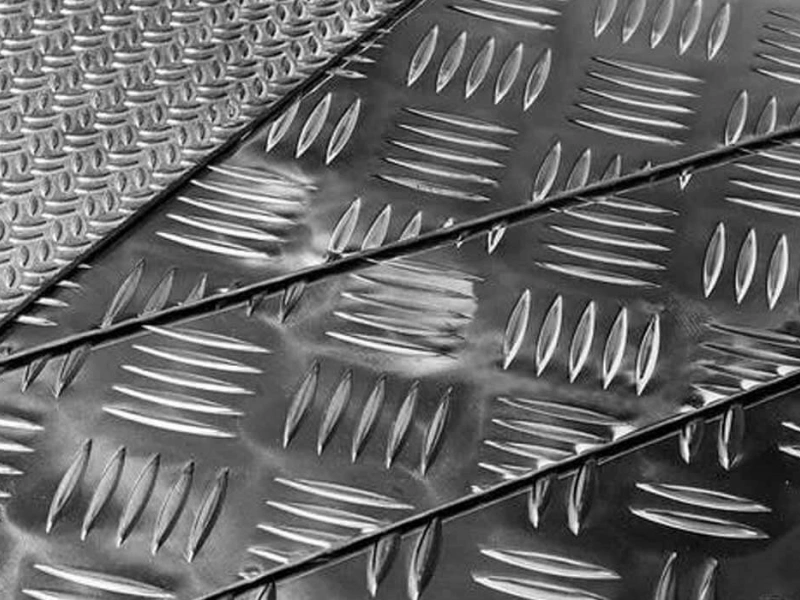

Aluminium checkered plates, also known as aluminum tread plates or diamond plates, are widely used for flooring, transportation, and industrial applications. Their raised pattern design provides anti-slip performance and enhances visual appeal. Made from high-quality alloys like 1050, 1100, 3003, 3105, 5052, and 5754, these plates are ideal for both commercial and residential use.

| Item | Details |

|---|---|

| Commodity | 1050, 1100, 3003, 3105, 5052, 5754 |

| Temper | H114, H22, H24, H14, O |

| Thickness | 1.0mm – 8.0mm |

| Width | 500mm – 2200mm |

| Length | Up to 6500mm |

Custom sizes are available upon request.

Aluminium checkered plates are commonly used in:

When selecting the appropriate aluminium checker plate, consider:

Aluminum checkered plates are lighter, corrosion-resistant, and easier to cut and install compared to steel plates. They’re ideal for applications where weight matters and rust protection is important.

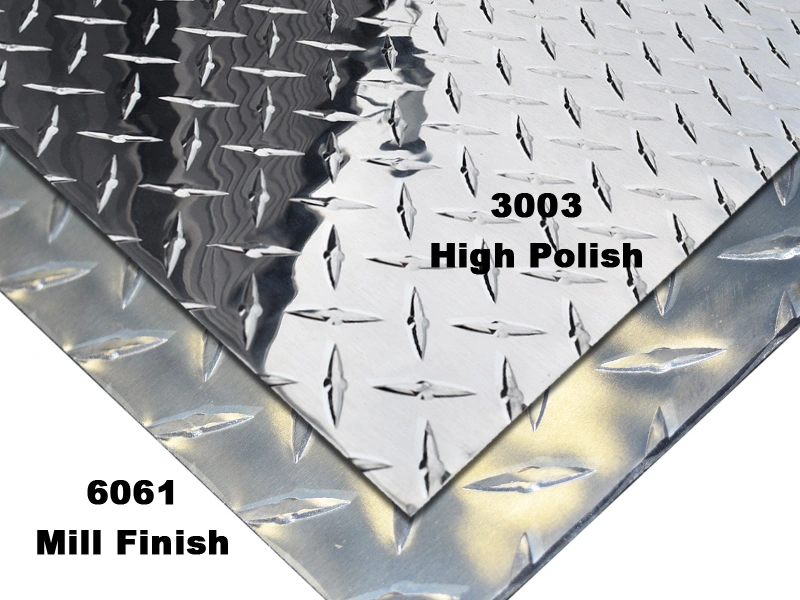

| Alloy | Best For | Key Property |

|---|---|---|

| 1050/1100 | Decorative uses | Excellent formability |

| 3003 | General purpose | Good strength & corrosion resistance |

| 5052 | Marine applications | Highest corrosion resistance |

| 5754 | Structural uses | High strength & weldability |

| Factor | Aluminum | Steel |

|---|---|---|

| Weight | Lighter (easier to handle) | Heavier |

| Corrosion | Doesn’t rust | Requires coating |

| Cost | Higher initial cost | Lower upfront price |

| Maintenance | Minimal | Needs repainting |

| Lifespan | Longer in harsh environments | Shorter unless maintained |

Recommendation: Choose aluminum for outdoor, marine, or corrosive environments; steel may be better for heavy industrial uses where cost is primary concern.

A: The number indicates raised bars per inch – more bars = more slip resistance.

A: Yes, after proper cleaning and priming with etch primer.

A: 3-5mm provides ideal balance of strength and weight.

A: Yes, small samples available for material verification.

✔ MOQ: 1 ton (smaller orders negotiable)

✔ Lead Time: 7-10 days for standard sizes

✔ Payment: T/T, L/C, Western Union

Contact Us Today for competitive pricing on aluminum checkered plates!