Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

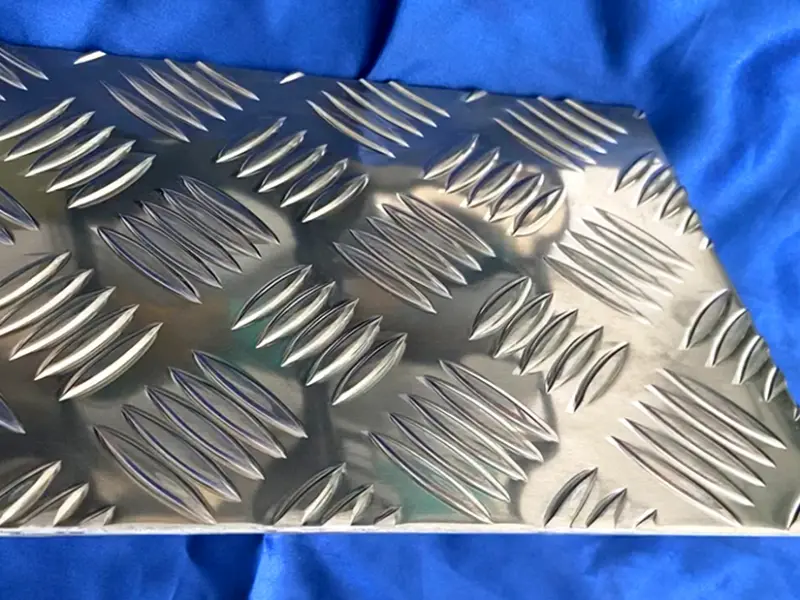

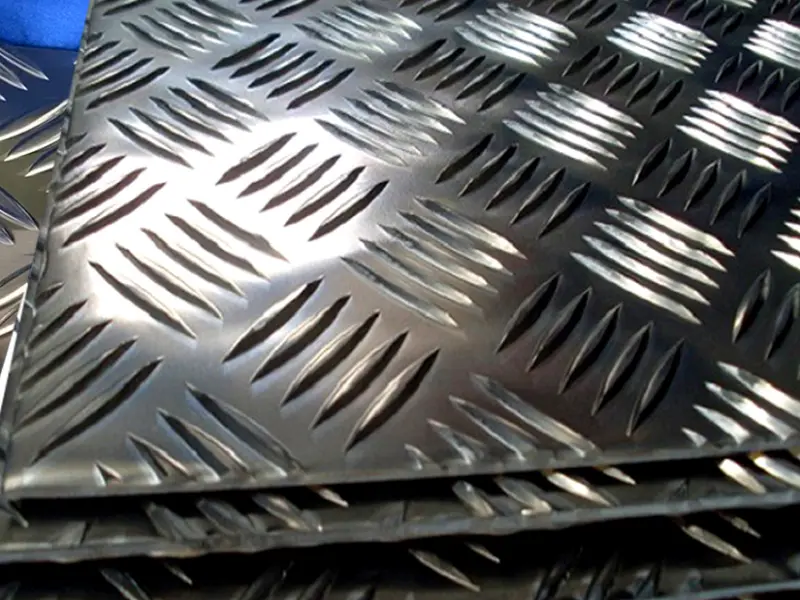

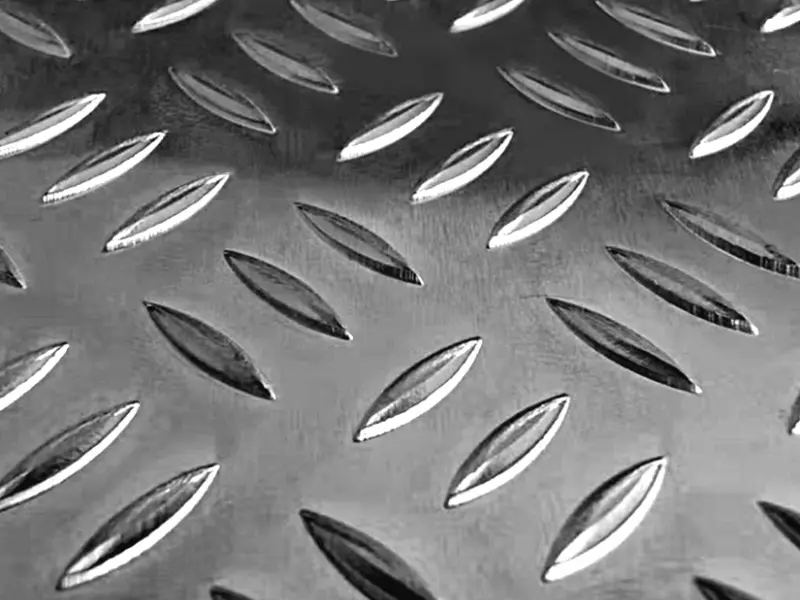

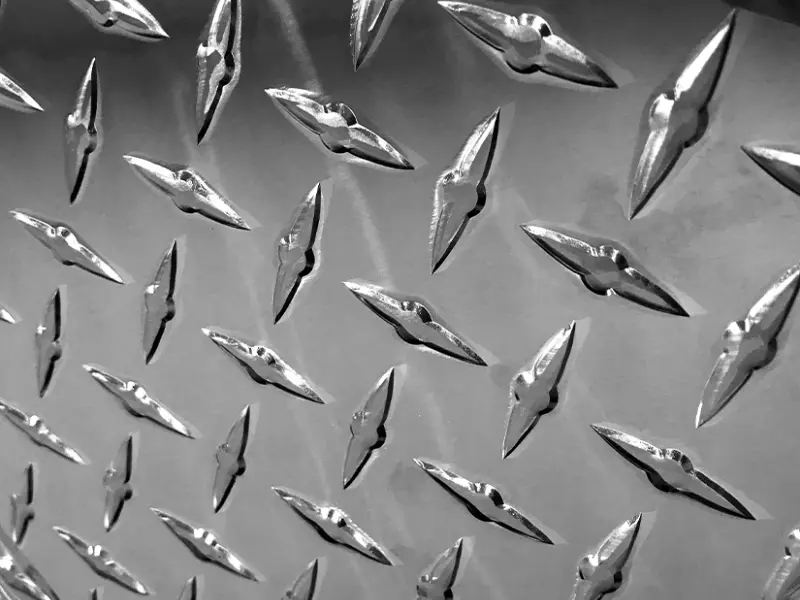

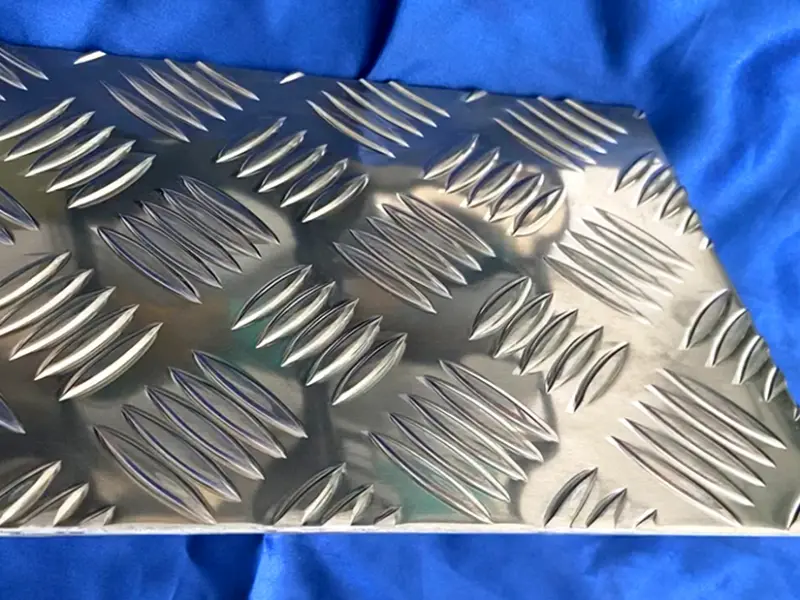

The checkered plate diamond pattern is a strong and lightweight aluminum or steel sheet with a raised diamond-shaped surface. This design is not only decorative but also highly functional, offering anti-slip, durability, and easy maintenance. Factories produce checkered plates in many alloys, thicknesses, and sizes to fit different projects.

| Classification | Description |

|---|---|

| Diamond Pattern Plate | Classic raised diamond shapes for slip resistance |

| Five-Bar Plate | Parallel bars for flooring and platforms |

| Embossed Plate | Decorative finish for walls and panels |

| Anodized Plate | Extra corrosion resistance and long life |

Checkered plates come in various thicknesses to fit lightweight or heavy-duty applications.

| Thickness (mm) | Application |

|---|---|

| 1.5 – 2.5 mm | Decorative walls, ceilings, light flooring |

| 3 – 4 mm | Warehouse floors, vehicle interiors |

| 5 – 6 mm | Truck beds, ramps, loading platforms |

| 7 – 8 mm | Industrial flooring, ship decks |

Different alloys are used for strength, corrosion resistance, and durability.

| Alloy | Features | Applications |

|---|---|---|

| 1060 | High purity, easy to process | Decoration, interior panels |

| 3003 | Corrosion resistance, good strength | Kitchens, warehouses |

| 5052 | High durability, marine resistance | Ships, ramps, trucks |

| 6061 | Strongest, mechanical strength | Heavy-duty flooring, industry |

This type is made from a single layer of aluminum.

Composite plates combine aluminum layers with a polyethylene or honeycomb core.

Perforated plates have holes along with the raised diamond surface.

This plate is covered with protective coatings such as PE, PVDF, or powder paint.

Factories that produce checkered plate diamond patterns follow these steps:

To ensure safe delivery, checkered plates are packed carefully:

Checkered plates are widely used because of their anti-slip surface, corrosion resistance, and modern look.

| Parameter | Value |

|---|---|

| Standard Size | 4×8 ft (1220×2440 mm) |

| Thickness Range | 1.5 – 8 mm |

| Alloy Options | 1060, 3003, 5052, 6061 |

| Surface Finish | Mill finish, polished, anodized |

| Pattern | Diamond, 5-bar |

❓ What is a checkered plate diamond pattern?

It is a metal sheet with raised diamond shapes for anti-slip and decoration.

❓ What thickness is best for flooring?

For heavy-duty floors, 5–6 mm is recommended. For light decoration, 1.5–2.5 mm is enough.

❓ Which alloys are most popular?

The most used alloys are 3003 (corrosion resistant), 5052 (marine use), and 6061 (industrial).

❓ Can I order custom sizes?

Yes, factories can cut sheets into any size required.

❓ Is it suitable for outdoor use?

Yes, especially with anodized or coated plates, which resist weather and UV.

❓ How are checkered plates packed for export?

They are packed on wooden pallets with waterproof film and steel straps.