Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Stucco embossed aluminum coil features a textured surface mimicking traditional stucco finish, created through precision rolling. These coils combine aluminum’s lightweight durability (2.7g/cm³ density) with enhanced thermal performance. Pre-painted coils maintain color consistency for 20+ years without fading.

The main properties include:

| Property | Detail |

|---|---|

| Surface | Stucco embossed texture |

| Finish | Bright, anti-reflective |

| Durability | Resistant to scratches and dents |

| Corrosion Resistance | Suitable for humid and outdoor use |

| Weight | Lightweight, easy handling |

There are different stucco embossed aluminum coil types used in insulation projects. Each type has unique features and applications. Choosing the right one helps improve durability, energy efficiency, and cost performance.

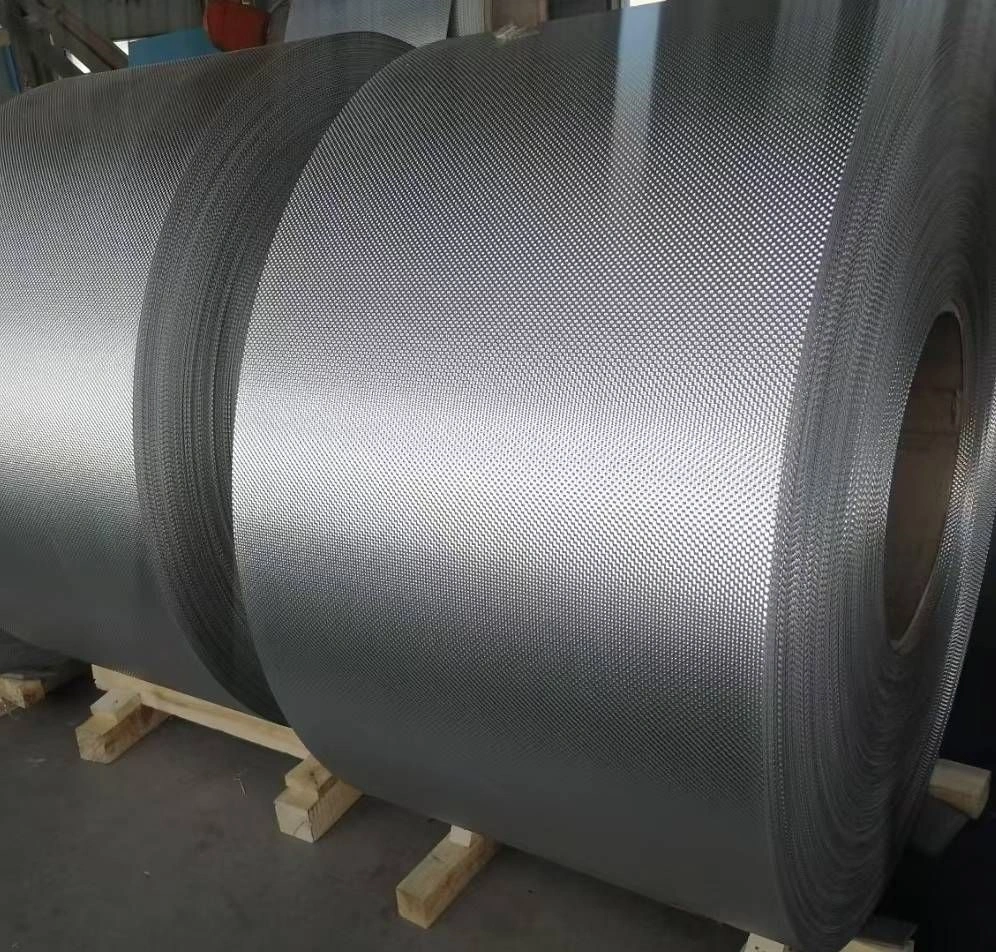

Embossed aluminum foil is thin, lightweight, and flexible. It is mainly used for wrapping insulation materials, such as mineral wool or foam boards. The foil acts as a protective layer to reduce heat loss, prevent moisture, and extend the service life of insulation systems.

This type is designed for strong protection of pipelines and ducts. The stucco embossed surface improves mechanical strength and reduces reflectivity. It is often applied in industrial facilities, chemical plants, and HVAC systems. The jacketing roll provides resistance to corrosion and weather, ensuring long-term insulation performance.

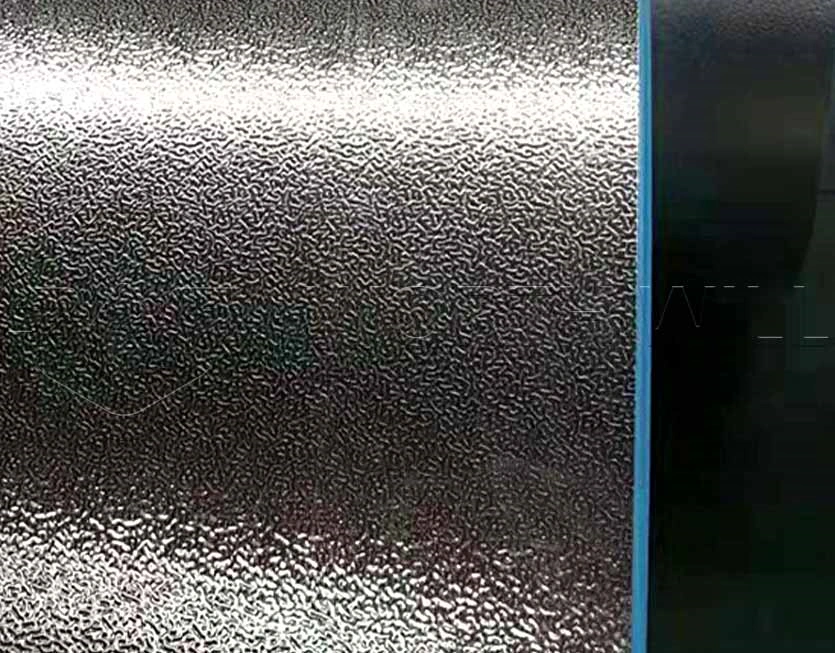

Coated aluminum coil comes with PE or PVDF color coating. This finish enhances corrosion resistance, UV protection, and aesthetic appearance. It is ideal for roofing, wall insulation, and exterior pipelines where both durability and design matter. The coated surface also makes cleaning and maintenance easier.

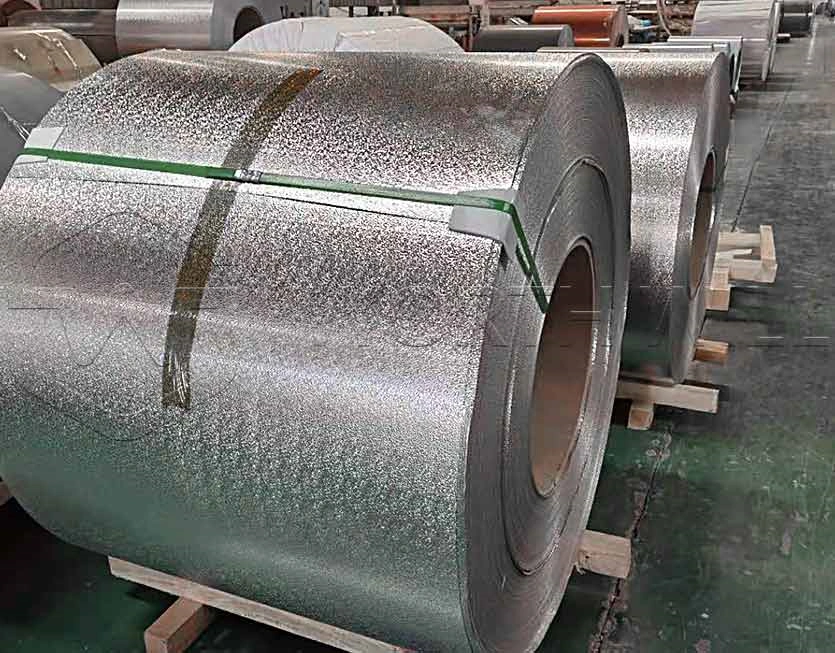

China embossed aluminum coil is a cost-effective solution widely used in global projects. It provides reliable quality with competitive prices, making it suitable for large-scale insulation projects, cold storage facilities, and construction works. Many international buyers choose this type for its balance of quality and affordability.

Stucco embossed aluminum coils are produced in various widths, lengths, and thicknesses.

| Thickness (mm) | Width (mm) | Length | Application |

|---|---|---|---|

| 0.2 – 0.4 | 500 – 1250 | Coil | Light cladding, insulation |

| 0.5 – 0.7 | 600 – 1500 | Coil or sheet | Cold rooms, wall panels |

| 0.8 – 1.0 | 800 – 1600 | Coil or sheet | Industrial insulation, roofs |

| 1.2 – 1.5 | 1000 – 1600 | Coil | Heavy-duty projects |

Different alloys provide different performance.

| Alloy | Feature | Best Use |

|---|---|---|

| 1060 | High purity, good corrosion resistance | General cladding, jacketing |

| 3003 | Stronger, excellent rust resistance | Cold rooms, food storage |

| 5052 | High strength, marine grade | Coastal areas, chemical plants |

| Packaging Type | Description |

|---|---|

| Eye to Sky | Easy to load with crane |

| Eye to Wall | For container transport |

| Wooden Pallets | Safe sheet packaging |

| Protective Film | Prevents scratches |

Common stucco embossed aluminum coil dimensions:

| Property | Range | Industry Standard | Common Applications |

|---|---|---|---|

| Thickness | 0.4mm – 1.5mm | 0.7mm | Wall cladding, roofing |

| Width | 800mm – 1600mm | 1250mm | Facade systems |

| Coil Weight | 3-10 tons | 5 tons | Large construction sites |

| Tensile Strength | 100-150 MPa | 130 MPa | Structural components |

Building & Construction

Transportation

Specialty Uses

Stucco aluminum vs other metals (per m²):

| Characteristic | Aluminum Coil | Galvanized Steel | Copper |

|---|---|---|---|

| Weight | 2.8kg | 7.5kg | 8.9kg |

| Corrosion Life | 30+ years | 15 years | 50 years |

| Thermal Conduc | 205 W/mK | 50 W/mK | 401 W/mK |

| Cost (USD) | $18-25 | $12-18 | $40-60 |

Stucco embossed aluminum coil delivers:

1. Why choose stucco embossed aluminum coil instead of plain aluminum?

The embossed surface is stronger, more durable, and hides scratches better.

2. What is the most common thickness?

Most cold room and insulation projects use 0.4–0.8 mm.

3. Can I order custom sizes?

Yes, coils and sheets can be cut to size according to your needs.

4. Which alloy is best for outdoor projects?

3003 and 5052 alloys are recommended for corrosion resistance.