Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

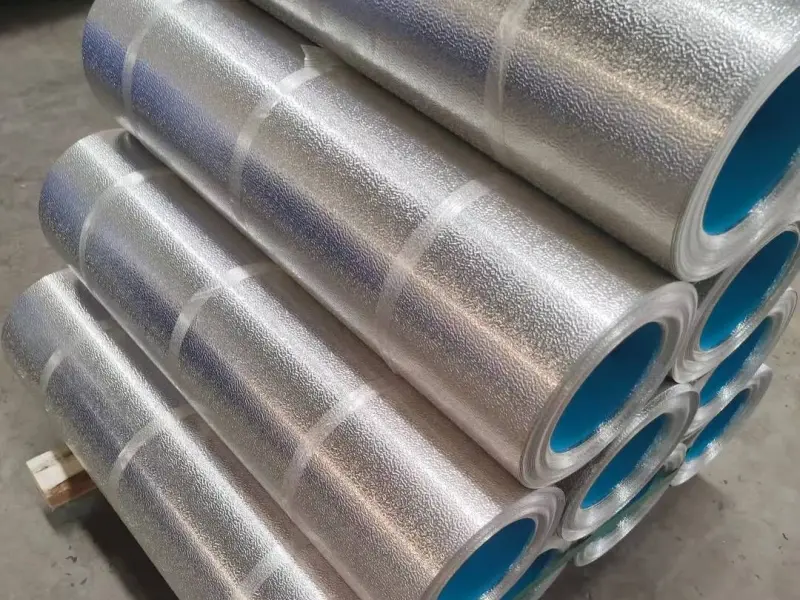

Stucco embossed aluminum roll for insulation offers excellent protection, enhanced performance, and a professional finish, making it a go-to choice for various insulation projects. Let’s explore why this material is so highly valued.

The stucco embossed aluminum roll provides a powerful combination of durability, efficiency, and aesthetics for your insulation systems. Its unique properties ensure long-term performance and protection.

| Feature Category | Key Benefits |

|---|---|

| Durability & Protection | Acts as a robust shield for underlying insulation, protecting against physical damage, moisture, and harsh environmental elements. This extends the lifespan and effectiveness of the insulation. |

| Enhanced Insulation | The embossed surface not only adds rigidity but also improves thermal performance. It helps reduce radiant heat transfer and airflow, contributing to better overall insulation efficiency and energy savings. |

| Lightweight & Easy Install | Despite its strength, stucco embossed aluminum roll is lightweight, simplifying handling, transport, and installation. It can be easily cut, bent, and formed to fit various shapes, reducing labor time and costs. |

| Corrosion Resistance | Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and corrosion. This is vital for outdoor use or in moist and chemical-prone environments, ensuring the longevity of your insulation. |

| Aesthetic Appeal | The distinctive stucco embossed finish provides a clean, modern, and professional look, which is important for visible installations where appearance is a consideration. It also reduces glare. |

| Cost-Effectiveness | Given its durability and long service life, stucco embossed aluminum roll for insulation offers excellent long-term value. Its ability to protect insulation reduces the need for frequent maintenance and replacement, leading to significant savings over time. |

Understanding the specific features helps you appreciate the functional advantages of this material in diverse insulation applications.

| Feature Name | Description |

|---|---|

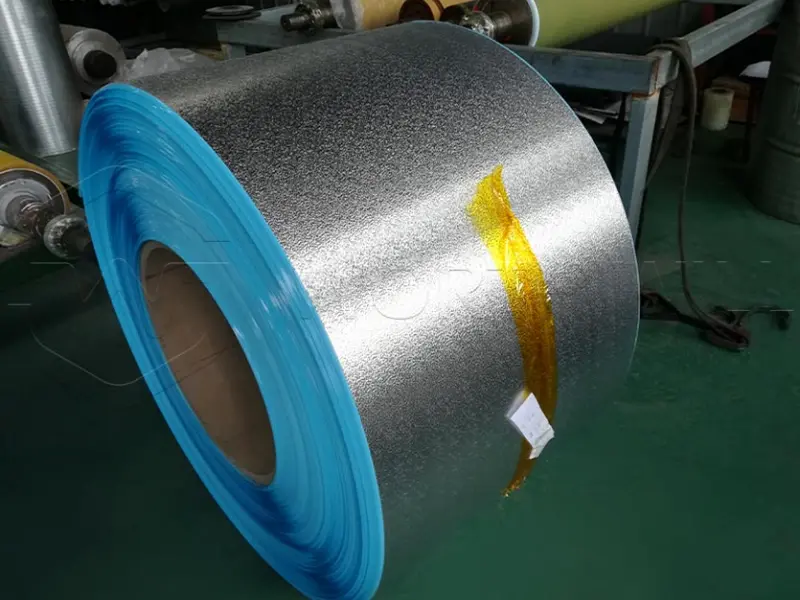

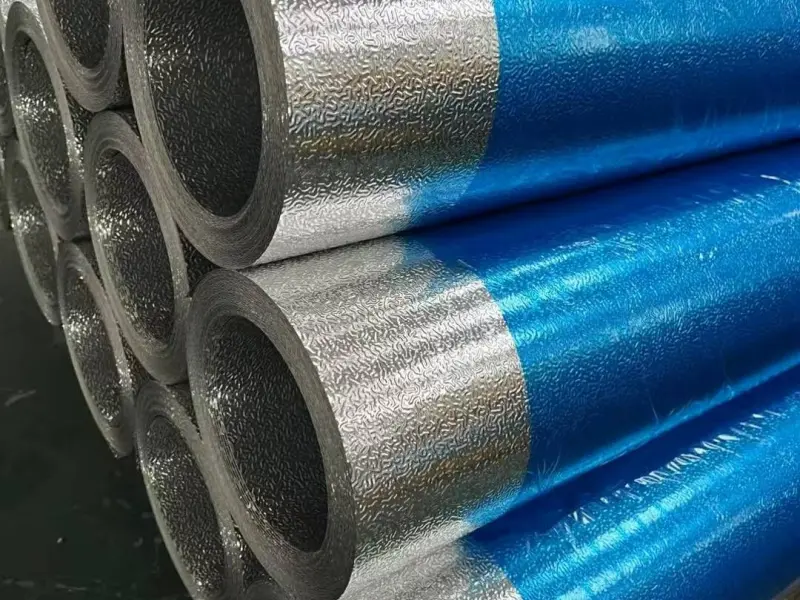

| Embossed Surface | The signature “stucco” pattern. This textured finish increases surface area, enhances rigidity, disperses light (reducing glare), and provides a unique visual appeal. It’s a key identifier of stucco embossed aluminum roll. |

| Material Composition | Made from high-quality aluminum alloys (e.g., 1050, 1060, 3003, 3105 series). These alloys are chosen for their excellent formability, corrosion resistance, and good thermal properties, ensuring consistent performance. |

| Varying Thicknesses | Available in a range of gauges (e.g., 0.3mm to 1.5mm), allowing selection based on required protection, flexibility, and application demands. Thicker rolls offer more robust protection. |

| Roll Form Supply | Supplied in large rolls, making it efficient for covering extensive areas with minimal seams. This format simplifies transportation and significantly speeds up installation processes compared to sheet formats. |

| Corrosion Resistant | Inherently resistant to corrosion, especially when compared to other metals, making it ideal for outdoor, marine, or industrial environments where moisture and chemical exposure are concerns. |

| Lightweight Property | Aluminum’s low density contributes to the overall light weight of the roll, which reduces structural load, simplifies handling, and lowers shipping costs. This is a significant advantage for large-scale projects. |

The versatility of stucco embossed aluminum roll for insulation makes it indispensable across numerous industries. Here are some primary application areas:

| Specification Category | Common Values/Types | Description |

|---|---|---|

| Aluminum Alloy | 1050, 1060, 3003, 3105 (e.g., Al-1050, Al-3003) | These are popular choices for their balance of formability, corrosion resistance, and moderate strength. 3003/3105 offer slightly higher strength for more demanding applications. |

| Temper (Hardness) | H14, H24 (e.g., H-14, H-24) | Defines the material’s hardness and workability. H14 temper is common for its good balance of formability and strength, while H24 is slightly harder and offers more rigidity. |

| Thickness Range | 0.3mm to 1.5mm (e.g., 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm) | Measured in millimeters, this dictates the protective strength and flexibility. |

| Standard Widths | 800mm to 1500mm (e.g., 1000mm, 1200mm, 1250mm) | Common widths are selected to minimize cutting waste and seams for typical insulation dimensions. Custom widths may be available for specific project needs. |

| Roll Lengths | 25m, 50m, 100m, 200m+ (e.g., 50-meter roll, 100-meter roll) | Rolls are provided in various lengths to suit project scale, from smaller jobs to very large industrial installations. Longer rolls reduce interruptions during application. |

| Surface Finish | Stucco Embossed (e.g., standard stucco, fine stucco) | The distinctive textured pattern. Different patterns (e.g., “orange peel” or “fine stucco”) may be available, all designed to enhance rigidity and aesthetics. |

| Protective Film | Optional (e.g., PE film on one side) | A transparent or colored plastic film can be applied to one side to protect the aluminum surface from scratches and damage during transportation, storage, and installation. |

| Compliance Standards | ASTM B209, EN 485, GB/T 3880 (e.g., meets ASTM B209 for aluminum sheet) | Reputable suppliers ensure their stucco embossed aluminum roll for insulation adheres to international material and quality standards, ensuring consistency and reliability. |

Making an informed choice ensures the best performance and value for your insulation project.

| Selection Factor | Considerations |

|---|---|

| Application Environment | Analyze: Is it indoor or outdoor? What are the temperature extremes, moisture levels, and potential exposure to chemicals or UV radiation? This will guide the required alloy and temper for corrosion resistance and durability. |

| Required Protection | Determine: What level of physical impact or abrasion resistance is needed? This directly influences the necessary thickness of the stucco embossed aluminum roll. Thicker gauges offer more robust protection. |

| Formability Needs | Evaluate: Will the aluminum need to be bent, formed, or wrapped around complex shapes? If so, a more flexible temper (like H14) and potentially a thinner gauge might be preferred for easier manipulation during installation. |

| Budget & Cost-Efficiency | Balance: Consider the initial cost versus long-term benefits. While thicker or specialized alloys may have a higher upfront cost, their extended lifespan and reduced maintenance can result in significant overall savings for your stucco embossed aluminum roll. |

| Supplier Reputation | Verify: Choose a supplier that provides clear specifications, material certifications, and good customer support. This ensures you receive high-quality stucco embossed aluminum roll for insulation that meets your project’s standards. |

For optimal performance, proper installation of your stucco embossed aluminum roll for insulation is crucial. Always consult the manufacturer’s guidelines and industry best practices. Ensure that the underlying insulation is dry and clean before applying the aluminum jacketing. In very humid or outdoor environments, consider using a moisture barrier between the insulation and the aluminum roll.

| Thickness | Price per m² | Coverage per Roll | Installation Cost |

|---|---|---|---|

| 0.08mm | $1.50 – $2.50 | 50m² (100m roll) | $1.00 – $2.00/m² |

| 0.10mm | $2.00 – $3.00 | 50m² (100m roll) | $1.20 – $2.20/m² |

| 0.12mm | $2.50 – $3.50 | 50m² (100m roll) | $1.50 – $2.50/m² |

| Material | Advantages | Disadvantages |

|---|---|---|

| Plain Aluminum Foil | Lower cost | Less durable, no texture |

| Reinforced Foil | Higher strength | More expensive, less flexible |

| Vinyl Barriers | Good moisture resistance | Lower temperature resistance |

| Fabric Reinforced | Tear resistant | Higher cost, less reflective |

Routine Maintenance:

Repair Methods:

Q: Can it be used in direct contact with insulation?

A: Yes, it’s designed for direct application over insulation materials

Q: How does the stucco pattern help?

A: It hides imperfections and reduces glare while maintaining functionality

Q: Is it suitable for outdoor use?

A: Yes, when properly installed and protected from direct weather exposure

Q: Can it be painted?

A: Not recommended as painting reduces thermal reflectivity

Q: How to handle seams and joints?

A: Overlap by 100mm and seal with approved tape or adhesive