Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

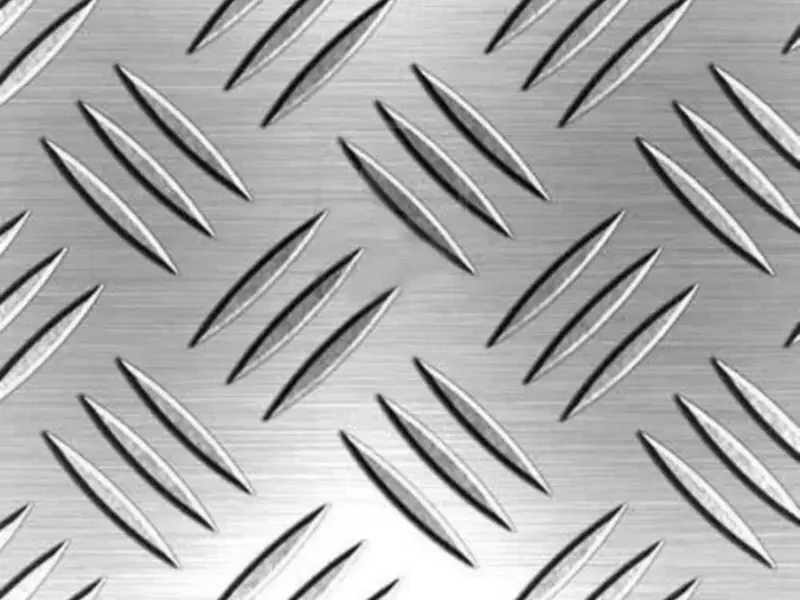

Aluminum checkered plate factories have wide applications in industrial flooring, vehicle platforms, stair treads, and decorative applications due to their anti-slip surface, durability, and lightweight properties. Aluminum checkered plate factories produce sheets in various alloys, thicknesses, and sizes, making them suitable for a wide range of projects.

| Feature | Description |

|---|---|

| Material | Aluminum alloy 5052, 6061, 3003 |

| Thickness | 1mm – 12mm (customizable) |

| Width | 1000mm – 2000mm |

| Length | Up to 6000mm or cut to size |

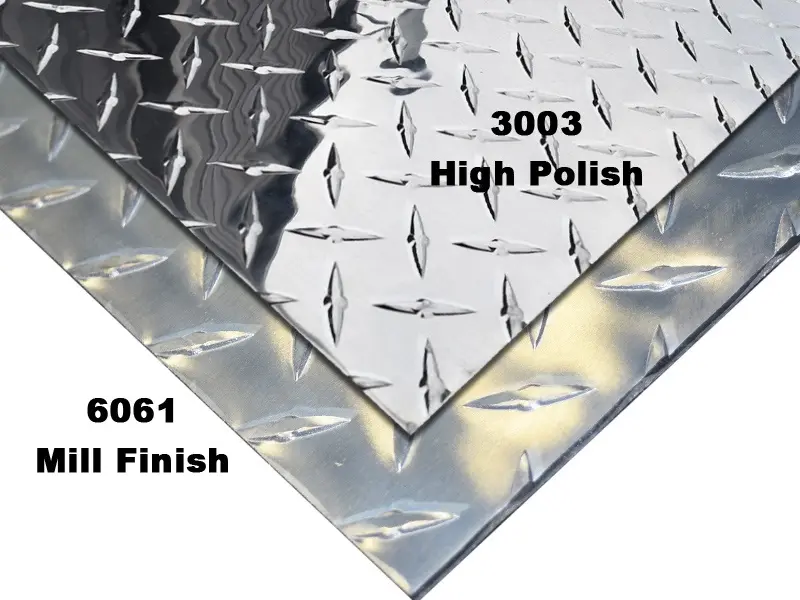

| Surface Pattern | Five-bar, diamond, or round raised patterns |

| Finish | Mill finish, brushed, or polished |

These specifications ensure high-quality plates for industrial and decorative use.

| Alloy | Properties | Applications |

|---|---|---|

| 5052 | Excellent corrosion resistance, flexible | Marine platforms, outdoor walkways |

| 6061 | Strong and durable | Industrial platforms, heavy-duty ramps |

| 3003 | Good corrosion resistance, cost-effective | Decorative panels, light-duty flooring |

Selecting the right alloy ensures long-lasting performance in any environment.

Reputable aluminum checkered plate factories maintain strict quality standards:

Quality Certification Table:

| Standard | Region | Coverage | Importance |

|---|---|---|---|

| ISO 9001 | Global | Quality Management | Essential |

| ASTM B632 | USA | Aluminum Alloy Standards | Required for US market |

| EN 485 | Europe | Technical Specifications | Required for EU market |

| GB/T 3880 | China | National Standards | Important for Asian market |

Selecting reliable aluminum checkered plate factories requires careful evaluation:

Supplier Evaluation Criteria:

| Criteria | Importance | What to Look For |

|---|---|---|

| Production Capacity | High | 100+ tons monthly output |

| Quality Control | High | ISO certification, testing equipment |

| Experience | Medium-High | 5+ years in business |

| Customization | Medium | Willingness to do small custom orders |

| Delivery Time | Medium | 15-30 days for standard orders |

Aluminum checkered plate factories are located worldwide:

Regional Factory Analysis:

| Region | Number of Major Factories | Price Level | Quality Rating | Export Experience |

|---|---|---|---|---|

| China | 50+ | $ | Good to Excellent | Extensive |

| Europe | 20+ | $$$ | Excellent | Moderate |

| North America | 15+ | $$ | Very Good | Limited |

| Southeast Asia | 10+ | $ | Good | Growing |

Understanding pricing from aluminum checkered plate factory:

Cost Breakdown Table:

| Cost Component | Percentage | Factors Affecting Cost |

|---|---|---|

| Raw Material | 60-70% | Aluminum prices, alloy type |

| Manufacturing | 15-25% | Electricity, labor, maintenance |

| Transportation | 5-10% | Distance, shipping method |

| Overhead | 5-10% | Factory maintenance, administration |

MOQ Comparison Table:

| Factory Size | Typical MOQ | Payment Terms | Sample Policy |

|---|---|---|---|

| Large Factories | 5-10 tons | 30% deposit | Paid samples |

| Medium Factories | 1-5 tons | 50% deposit | Free samples for serious buyers |

| Small Factories | 500kg-1 ton | 100% advance | Free small samples |

Q1: Can I order custom sizes?

Yes, aluminum checkered plates can be cut to any size to suit your project.

Q2: Which pattern is best for anti-slip?

Diamond and five-bar patterns provide the best traction.

Q3: Are these plates corrosion-resistant?

Alloys like 5052 and 6061 are highly resistant to corrosion, suitable for outdoor use.

Q4: How thick should the plate be for heavy-duty applications?

For industrial floors or ramps, 6–12mm is recommended depending on load requirements.