Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

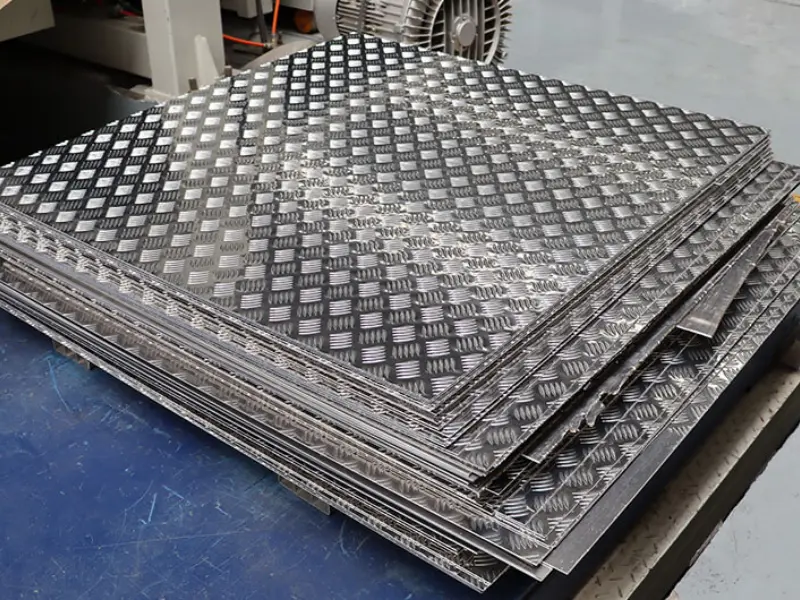

Aluminum checkered plates are widely used in construction, industrial flooring, transportation, and architectural applications. Choosing a reliable aluminum checkered plate manufacturer ensures high-quality products, timely delivery, and competitive prices. Whether for industrial, architectural, or decorative applications, these plates provide strength, durability, and aesthetic appeal.

An aluminum checkered plate is a metal sheet with raised patterns on one side. The patterns provide:

Common patterns include diamond, five-bar, lentil, and mirror finish. These plates are lightweight yet strong, making them suitable for various industrial and decorative purposes.

| Alloy | Thickness (mm) | Width (mm) | Length (mm) | Pattern Type |

|---|---|---|---|---|

| 3003 H14 | 1 – 6 | 1000 – 1500 | 2000 – 6000 | Diamond, 5-bar |

| 5052 H32 | 1.5 – 8 | 1000 – 1500 | 2000 – 6000 | Lentil, Mirror |

| 6061 T6 | 2 – 10 | 1000 – 1500 | 2000 – 6000 | Custom |

Note: Manufacturers can produce custom sizes according to client requirements.

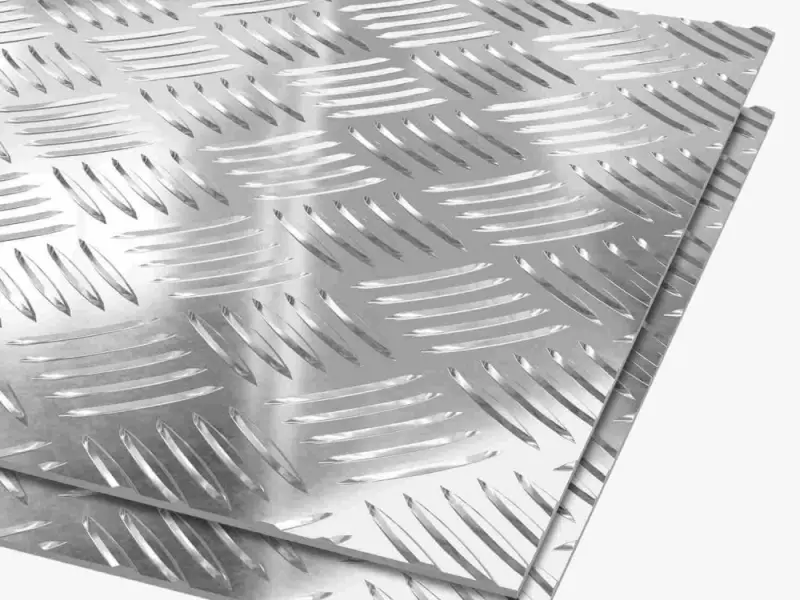

The five-bar aluminum plate features five parallel raised bars on the surface. This pattern enhances traction, especially in walkways, ramps, and pedestrian paths. It is strong, durable, and resistant to heavy foot traffic, making it suitable for warehouses and industrial environments.

The lentil pattern aluminum plate is characterized by small round bumps evenly distributed on the surface. It is commonly used in bus floors, elevators, and pedestrian areas, offering anti-slip properties while maintaining a smooth look. The lentil design provides comfort underfoot and long-term durability.

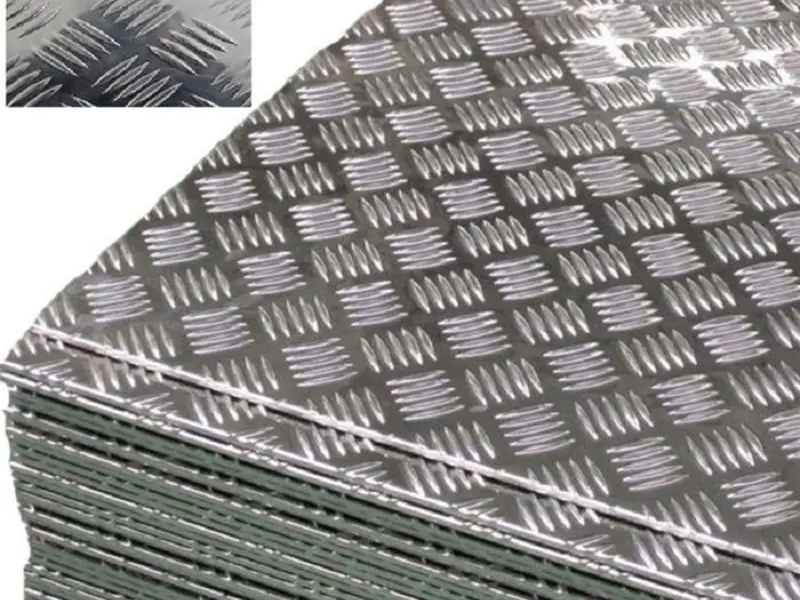

The checker or checkerboard aluminum plate has a uniform square or rectangular pattern. It has wide applciations for vehicle flooring, industrial platforms, and storage areas. The pattern enhances grip and reduces accidents, making it a reliable choice for heavy-duty applications.

The mirror finish aluminum plate is smooth and reflective, primarily used for decorative applications, interior design, and architectural elements. While it has a subtle pattern, its polished surface enhances visual appeal and adds aesthetic value to furniture, displays, and wall cladding.

The custom pattern aluminum plate allows clients to specify unique designs, shapes, or logos for branding, decoration, or functional purposes. This flexibility makes it suitable for signage, architectural projects, and specialty industrial applications, ensuring both functionality and personalized aesthetics.

Compared to other manufacturers, we offer consistency, long-term partnerships, and customized solutions.

Locating the best aluminum checkered plate manufacturers for your needs involves a systematic approach. With many aluminum tread plate suppliers in the market, careful selection ensures you get quality and value.

Online Research and Directories: Start by using search engines to find manufacturers. Look for industry directories and B2B platforms that list metal suppliers. Keywords like “best aluminum checkered plate manufacturer,” “aluminum tread plate suppliers,” or “custom aluminum checker plate” can yield good results.

Industry Trade Shows and Events: Attending trade shows is an excellent way to meet manufacturers directly, see their products, and discuss your requirements face-to-face. This also allows for networking and gaining insights into industry trends.

Request for Quotation (RFQ): Once you have a shortlist of potential aluminum checkered plate manufacturers, send out detailed RFQs. Include all necessary specifications: alloy type, pattern, dimensions (thickness, width, length), temper, quantity, and delivery requirements. This helps in getting accurate quotes and comparing offers.

Ask for Samples: For critical applications, request samples of their aluminum checker plate. This allows you to inspect the quality, finish, and pattern firsthand before committing to a large order.

Check References and Case Studies: A reliable manufacturer should be able to provide references from satisfied customers or case studies of previous projects. This offers real-world evidence of their capabilities and customer satisfaction.

Visit Facilities (If Possible): If the order is substantial, consider visiting the manufacturer’s facility. This gives you insight into their production processes, quality control, and overall operational standards.

By following these steps, you can confidently choose an aluminum checkered plate manufacturer that aligns with your quality expectations, budget, and project timelines.

| Package Type | Description |

|---|---|

| Internal | Protective plastic film |

| External | Wooden pallet or steel frame |

| Shipping | Sea, air, or express delivery |

| Delivery Time | 15–25 days depending on order size |

Q: What alloy is best for outdoor use?

A: 5052 H32 is recommended for excellent corrosion resistance.

Q: Can aluminum checkered plates be cut or bent?

A: Yes, they can be cut, welded, or bent easily.

Q: What thickness is suitable for flooring?

A: Usually 2 mm to 5 mm, depending on load requirements.

Q: Do you provide international shipping?

A: Yes, we ship to Europe, America, Asia, and other regions.